Core Products

Mach Technology was founded in 1996 and specializes in providing manufacturing enterprises with integrated software and equipment solutions for "Industry 4.0." The company is based in the rubber, plastics, chemical, cable and cable polymer materials, friction materials, and welding materials industries, providing digital solutions to global customers.

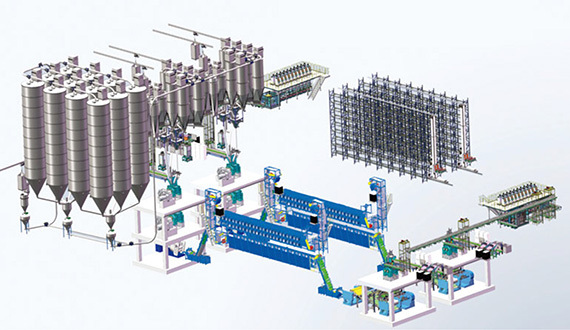

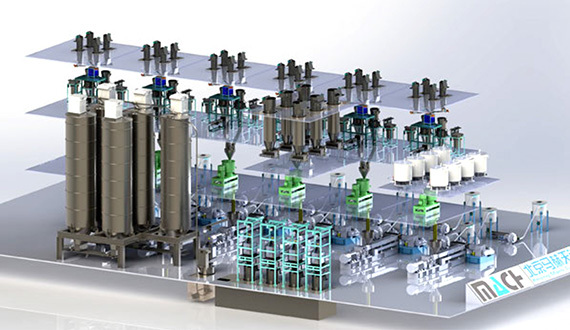

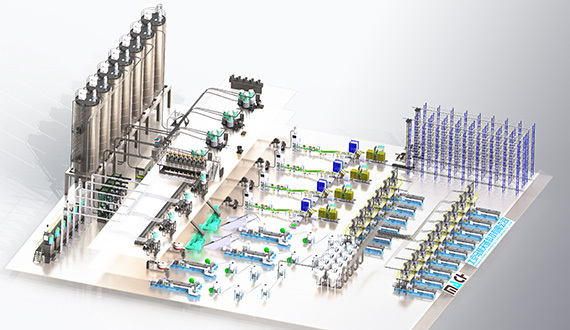

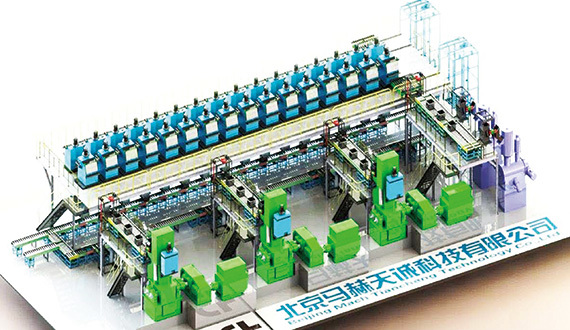

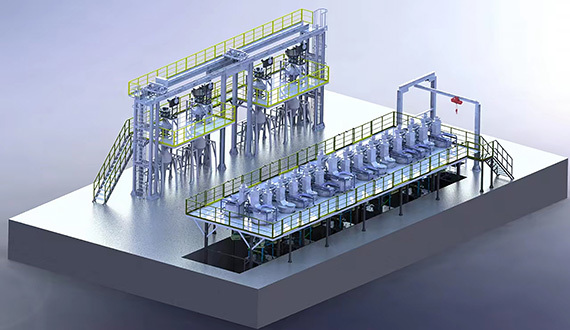

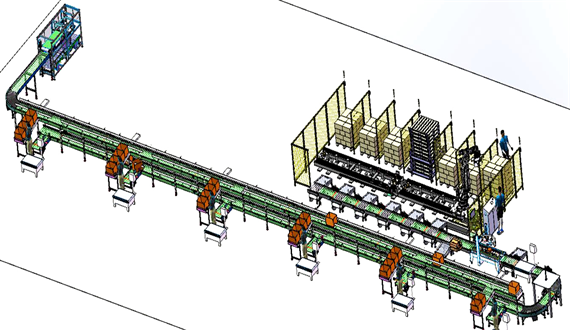

Auxiliary machine system, automatic batching system, centralized feeding system, automatic unpacking system, small material/auxiliary material automatic weighing and batching system, intelligent three-dimensional warehouse, intelligent logistics conveying system, industrial information management software,

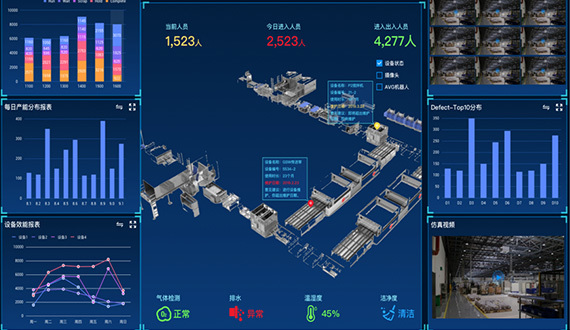

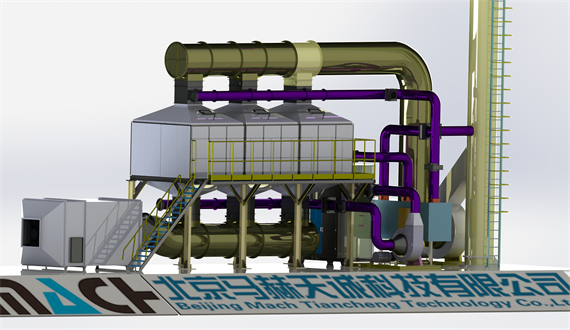

MES system, green environmental protection equipment, automatic detection and packaging system, etc., customized non-standard products and supporting services.

Mach Technology

Mach Tech, founded in 1996, specializes in providing manufacturing enterprises with integrated software and equipment solutions for "Industry 4.0," and is committed to the research and development of intelligent, green, and user-friendly intelligent equipment, continuously promoting the deep integration of information technology and industrialization.

Currently, the company has a professional team of 280+ experts, two R&D and manufacturing bases in Tianjin and Jiangsu, and five large offices in Hebei, Shandong, Guangdong, Chongqing, and Fujian.

The company was founded in

Domestic and International Users

Expert Team

Adopting a vertical and flat management mechanism to minimize communication costs and internal consumption, and maximize work efficiency and quality.

CHOOSE US

Reasons to choose us

Technological innovation principle: In accordance with the principle of "intelligent control, advanced technology, practical stability, simple operation, and convenient maintenance", with a "professional" spirit and "professional" attitude, through continuous innovation and improvement, effectively solve the production and management problems that users are concerned about, and achieve "user satisfaction, hand in hand innovation, and common development"

View details

I. Intelligent and environmentally friendly automatic batching system Internal mixer/kneader/banbury mixer upstream equipment/Powder/Fully Automatic Chemical Weighing and batching system、Mixer/kneader/extruder

II. Intelligent three-dimensional warehouse (rubber product three-dimensional warehouse, plastic and plastic product three-dimensional warehouse, wire and cable material three-dimensional warehouse......);

III. Intelligent logistics and transportation system (AGV/RGV, barcode/CCD image intelligent recognition system, WMS warehouse management software, portable management platform);

News center

Customized, according to the needs and actual situation of each customer, provide appropriate technical solutions and full personalized service, and pay attention to the potential needs of customers.

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn