Products

Hot Products

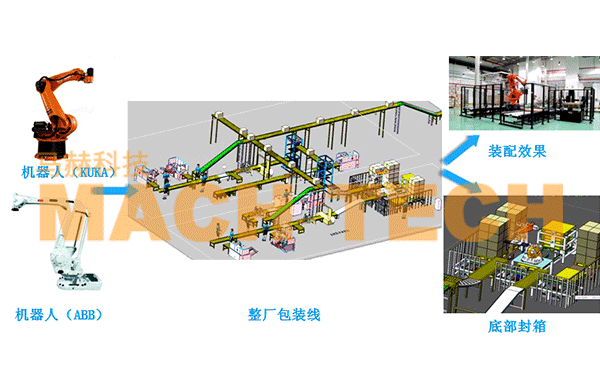

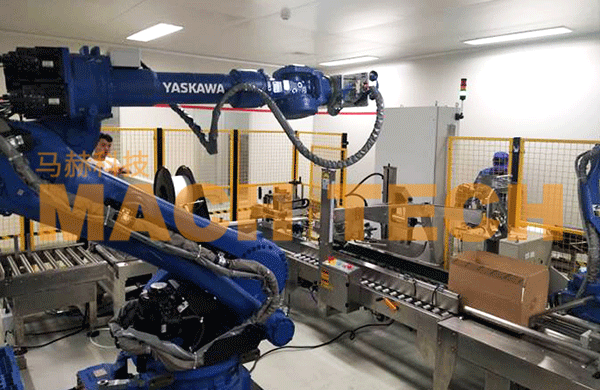

Our company selects high-end robotic arms from both domestic and international sources (commonly used brands include ABB, KUKA, etc.), with a self-designed pneumatic gripper at the front end and an adjustable flow valve for smooth operation. The robot arm base is made of welded carbon steel and is fixed to the ground. We have independently developed supporting application software for smooth and efficient control of the robot arm operation. The CCD sorting and stacking robot is equipped with a pallet gripper that can automatically grasp and place stacked pallets in the corresponding pallet area for product palletizing.

The CCD detection system uses industrial cameras to perform functions such as identification, measurement, positioning, and judgment. It converts the captured target into an image signal, which is then transmitted to a dedicated image processing system. Based on pixel distribution, brightness, and color information, the signal is converted into a digital signal. The image system performs various calculations on these signals to extract the target's features, and then controls the on-site equipment actions based on the judgment results.

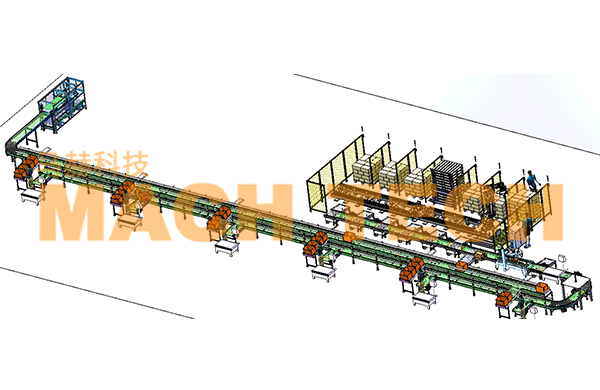

Automatic carton opening, packaging, and palletizing line

This system is equipped with an automatic unpacking machine, a double-layer logistics roller conveyor line, an automatic inkjet coder, an automatic folding and sealing machine, CCD barcode scanning and recognition software, an immediate printing and labeling machine, diversion and temporary storage conveyor, robot palletizing, RGV transfer and conveying pallet, and three-dimensional storage. Combined with warehouse management software, a host barcode management system, and automated logistics equipment interfaces, it achieves a high degree of automation in the entire process of finished product packaging production, thereby improving logistics turnover efficiency, ensuring the timeliness and accuracy of logistics supply, and realizing flexible storage functions.

This system is equipped with an automatic unpacking machine, a double-layer logistics roller conveyor line, an automatic inkjet coder, an automatic folding and sealing machine, CCD barcode scanning and recognition software, an immediate printing and labeling machine, diversion and temporary storage conveyor, robot palletizing, RGV transfer and conveying pallet, and three-dimensional storage. Combined with warehouse management software, a host barcode management system, and automated logistics equipment interfaces, it achieves a high degree of automation in the entire process of finished product packaging production, thereby improving logistics turnover efficiency, ensuring the timeliness and accuracy of logistics supply, and realizing flexible storage functions.

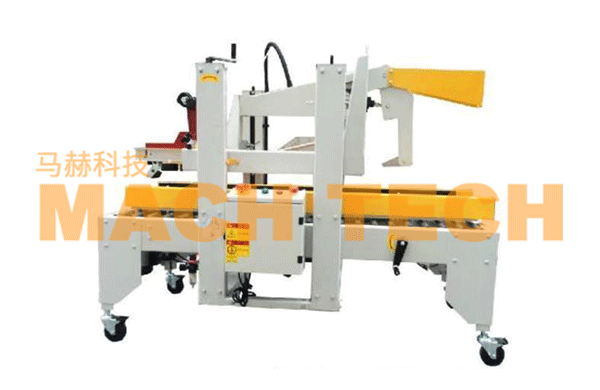

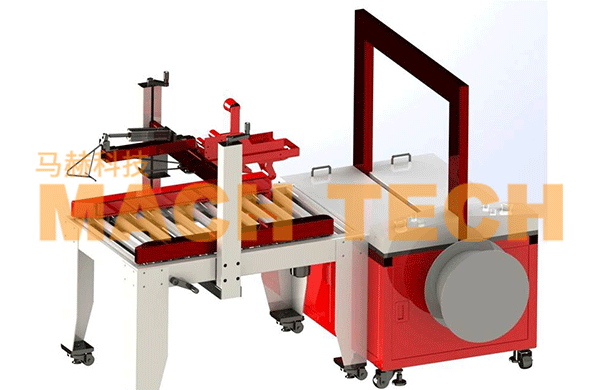

Automatic cardboard box sealing machine

This system is equipped with an automatic unpacking machine, a double-layer logistics roller conveyor line, an automatic inkjet coder, an automatic folding and sealing machine, CCD barcode scanning and recognition software, an immediate printing and labeling machine, diversion and temporary storage conveyor, robot palletizing, RGV transfer and conveying pallet, and three-dimensional storage. Combined with warehouse management software, a host barcode management system, and automated logistics equipment interfaces, it achieves a high degree of automation in the entire process of finished product packaging production, thereby improving logistics turnover efficiency, ensuring the timeliness and accuracy of logistics supply, and realizing flexible storage functions.

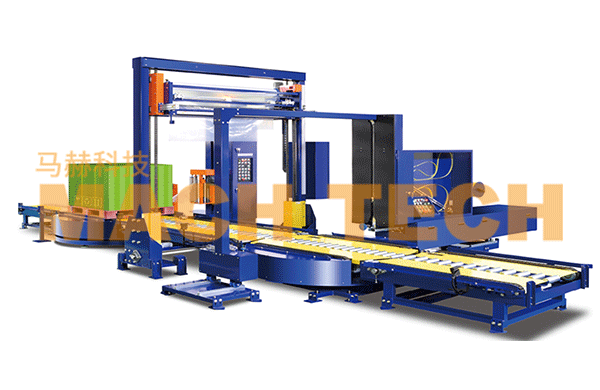

Automatic carton opening, packaging, and palletizing line

This system is equipped with an automatic unpacking machine, a double-layer logistics roller conveyor line, an automatic inkjet coder, an automatic folding and sealing machine, CCD barcode scanning and recognition software, an immediate printing and labeling machine, diversion and temporary storage conveyor, robot palletizing, RGV transfer and conveying pallet, and three-dimensional storage. Combined with warehouse management software, a host barcode management system, and automated logistics equipment interfaces, it achieves a high degree of automation in the entire process of finished product packaging production, thereby improving logistics turnover efficiency, ensuring the timeliness and accuracy of logistics supply, and realizing flexible storage functions.

This system is equipped with an automatic unpacking machine, a double-layer logistics roller conveyor line, an automatic inkjet coder, an automatic folding and sealing machine, CCD barcode scanning and recognition software, an immediate printing and labeling machine, diversion and temporary storage conveyor, robot palletizing, RGV transfer and conveying pallet, and three-dimensional storage. Combined with warehouse management software, a host barcode management system, and automated logistics equipment interfaces, it achieves a high degree of automation in the entire process of finished product packaging production, thereby improving logistics turnover efficiency, ensuring the timeliness and accuracy of logistics supply, and realizing flexible storage functions.

Automatic winding packaging machine

This system is equipped with an automatic unpacking machine, a double-layer logistics roller conveyor line, an automatic inkjet coder, an automatic folding and sealing machine, CCD barcode scanning and recognition software, an immediate printing and labeling machine, diversion and temporary storage conveyor, robot palletizing, RGV transfer and conveying pallet, and three-dimensional storage. Combined with warehouse management software, a host barcode management system, and automated logistics equipment interfaces, it achieves a high degree of automation in the entire process of finished product packaging production, thereby improving logistics turnover efficiency, ensuring the timeliness and accuracy of logistics supply, and realizing flexible storage functions.

Automatic paper bag packaging and palletizing production line

This production line can automatically package and palletize materials in both ton bags and 25kg small bags. The automatic ton bag packaging machine is a multi-purpose automatic quantitative packaging machine integrating electronic weighing, automatic unhooking, and dust removal. It includes a feeder, automatic bag hanging mechanism, bag blowing device, bag clamping mechanism, metering conveying unit, and control system. Workers manually hang the packaging bag straps on the hooks and place the inlet on the outlet. The clamping device automatically clamps the inlet for weighing and filling. After filling, the ton bag is automatically lowered to the conveyor, the hook is automatically detached, and the package is conveyed to the operator's workstation for manual sealing, completing the quantitative packaging of the ton bag.

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn