How to set up recipes for an automatic magnetic material dispensing system

Published Time:

2022-09-07

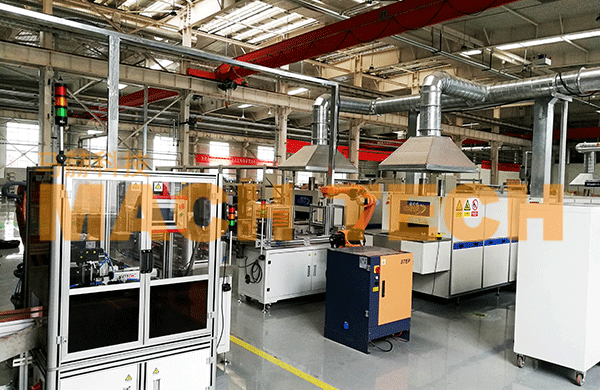

The automatic batching process of magnetic materials is a crucial step in factory production. Precise automatic batching of magnetic materials is a challenge in the production process. Labor costs are increasing, and precision requirements are becoming more stringent. Therefore, the implementation of an automatic batching system for magnetic materials is an irreversible trend. Let's explore how to set up recipes for an automatic magnetic material batching system!

Automatic batching of magnetic materials is a crucial step in factory production. Precise measurement in this process is challenging. With rising labor costs and increasing demands for accuracy, the implementation of an automated system is inevitable. Let's explore how to set up a recipe for an automatic magnetic material batching system!

Limitations of Manual Batching

After receiving the daily production schedule, raw material workers weigh each ingredient in sequence. They calculate the weight of each component based on the total quantity, then take materials from the respective bins, weigh them on an electronic scale, and package them. This process is labor-intensive, prone to errors, lacks real-time weight monitoring, and doesn't record production data, thus failing to guarantee consistent production quality. An automatic magnetic material batching system provides real-time monitoring of the weighing of powdered or liquid materials, mixing them according to a pre-selected ratio.

What are the common batching methods?

1. Centralized Control Batching System

This system typically involves sequentially adding two or more materials into a single weighing container.

Its features include compact structure and low investment.

2. Reactor Batching System

This system uses the reactor as the weighing container. Multiple raw materials are added sequentially during stirring, according to a preset order and weight. Its features include simultaneous addition and mixing, which increases measurement speed and reduces auxiliary equipment. Specialized technology eliminates the influence of stirring on weighing accuracy.

3. Distributed Control Batching System

This system typically uses a separate weighing container for each material, offering fast weighing speed and high measurement accuracy.

4. Hybrid Control Batching System

This system groups materials with similar weights into different weighing containers for measurement and mixing. Its features include fast weighing speed, high measurement accuracy, and moderate investment.

5. Mobile Control Batching System

This system mounts the weighing container on a reciprocating vehicle, collecting materials from different supply points for batching. It is characterized by handling multiple materials, complex recipes, and high positioning accuracy of the weighing vehicle.

Loss-in-Weight Feeder

What metering equipment is generally used in an automatic magnetic material batching system? Generally, such systems include loss-in-weight feeders, liquid metering devices, multi-component suction metering systems, and metering warehouses. Companies preparing to set up a magnetic material automatic batching system production line typically consider three factors: raw material accuracy, process requirements, and budget.

The above describes how to set up a recipe for an automatic magnetic material batching system. For more information, please contact us!

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn