What are the advantages of automatic plastic and resin batching?

Published Time:

2023-05-06

The automatic plastic and resin batching system monitors the condition of each raw material through sensors and uses a computer control system to precisely control the amount of each batching material, ensuring production accuracy and efficiency. Improved production efficiency; 2. Reduced labor costs; 3. Ensured consistent product quality; 4. Reduced waste generation; 5. Simple operation and low learning costs.

The automatic plastic material batching system monitors the status of each raw material through sensors and uses a computer control system to accurately control the amount of each batching material, ensuring production accuracy and efficiency.

1. Improve production efficiency; 2. Reduce labor costs; 3. Ensure product quality consistency; 4. Reduce waste generation; 5. Easy operation and low learning costs.

What problems will be encountered in the practical application of the automatic plastic material batching system?

1. The sensor accuracy is not high enough; 2. Excessive or insufficient batching leads to product quality problems; 3. The centrifugal hopper transportation method is not suitable for some raw materials; 4. The price difference between semi-automatic and fully automatic equipment is large.

How can the accuracy of the plastic material batching system be improved?

1. Use a touch screen display interface for control; 2. Adjust the sensor sensitivity; 3. Regularly maintain instruments and meters to maintain stability; 4. Select raw materials with high precision and good stability.

How to avoid product defects caused by color changes?

1. Use a special color difference detection device; 2. Use a special formula; 3. Timely maintenance and maintenance of equipment to avoid equipment failure.

What are the future development trends of automatic plastic material batching technology?

1. The emergence of higher-precision batching equipment; 2. The use of big data and artificial intelligence technology to improve production efficiency and reduce costs; 3. The application range of automatic plastic batching systems will be wider, especially in the field of high-end products.

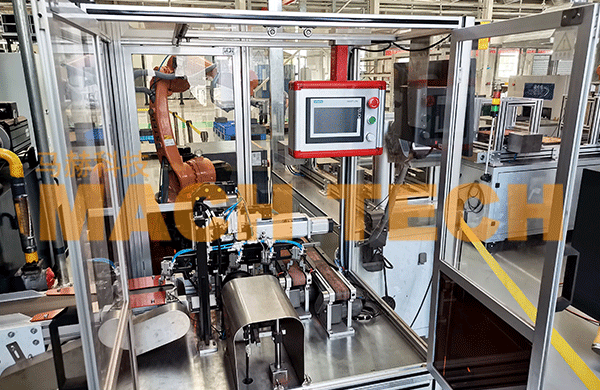

Plastic products are widely used in various industries. Accurate batching is required during the production process to ensure product quality. The automatic plastic material batching system is designed for this purpose. Let's take a closer look at this technology and its applications.

First, the automatic plastic material batching system controls the amount of each batching material by computer, achieving a high-precision and efficient production process. The raw materials involved in the batching process are diverse, and the proportion of each raw material in the finished product is different. If traditional manual batching is used, unbalanced proportions or large errors will lead to a decline in product quality, and even unqualified products. Using an automated batching system can accurately measure the weight and proportion of each raw material, reduce errors, and improve production efficiency and product quality.

Secondly, the advantages of the automated batching system are very obvious. First, it can significantly reduce the cost of manual batching while improving the accuracy of the proportion; second, it ensures product quality consistency and reduces product waste; and it is easy to operate and learn.

However, in practical applications, the automatic plastic material batching system still has some problems. First, the insufficient accuracy of the sensor may lead to errors in the batching amount; second, excessive or insufficient batching may also lead to product quality problems; in addition, the centrifugal hopper transportation method is not suitable for some raw materials, and the price difference between semi-automatic and fully automatic equipment is also large. To solve these problems, we can gradually optimize and improve the equipment, reduce the occurrence of failures, improve productivity, and reduce costs.

For the automatic plastic material batching system, how to improve the batching accuracy is also a relatively important issue. We can use methods such as touch screen display interface control, adjusting sensor sensitivity, regularly maintaining instruments and meters, and selecting raw materials with high precision and good stability to improve batching accuracy. In addition, we can also use color difference detection technology to avoid product defects caused by color changes, and timely maintenance of equipment should be carried out to avoid equipment failures.

What are the development trends of automatic plastic material batching technology? We can discuss this from the following three aspects: First, the emergence of higher-precision batching equipment; second, the use of big data and artificial intelligence technology to improve production efficiency and reduce costs; third, the application range of automatic plastic batching systems will be wider, especially in the field of high-end products.

In short, automatic plastic material batching technology is a technology worth promoting. It can improve production efficiency, ensure product quality, and reduce costs. At the same time, we also need to continuously improve and improve this technology to solve potential problems. With the continuous progress and development of science and technology, automatic plastic material batching technology will surely be able to better play its due role.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn