Characteristics of auxiliary machines on Mach Technology's refining machine

Published Time:

2021-06-04

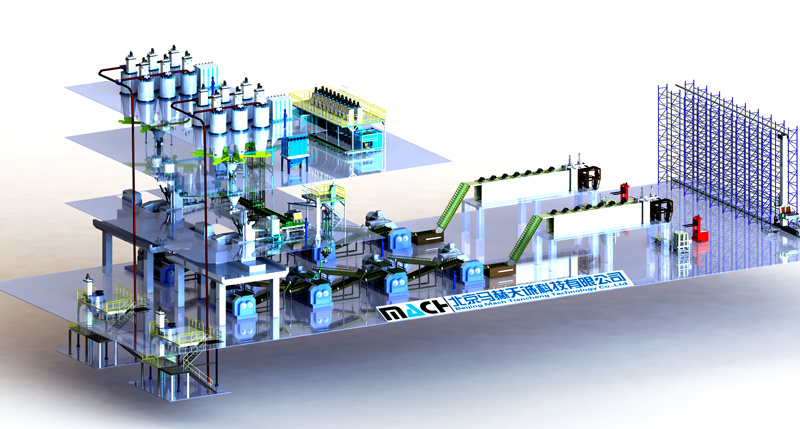

The Mahmi Refining Machine (Wanmali) auxiliary machine is a fully intelligent material (powder, granular, block, liquid, etc.) conveying, storage, metering, batching, and feeding system for the rubber industry, independently developed based on the introduction and absorption of advanced German and British technologies. It can be used with various specifications of 25-650L internal mixers. It mainly consists of five parts: carbon black (white material) part, oil part, rubber part, dust removal part, and the entire rubber mixing control system. The entire rubber mixing control system integrates the latest information technology with production management and rubber mixing technology, integrating the entire process control of rubber mixing production, production plan management, material management, and quality tracking management. It truly achieves integrated control and has its own software copyright; it plays an important role in improving management level, product quality, and product stability. After years of continuous technological innovation and improvement by our company, this system has been widely used in the rubber tire, rubber products, rubber hose and belt, wire and cable, and rubber miscellaneous parts industries, and has been well received by customers at home and abroad. Features: 1. Full-process control, monitoring, and recording of rubber mixing, enabling remote monitoring and after-sales support, improving management level; 2. Optimized mixing is achieved through integral calculation and logical control of parameters such as time, temperature, energy, speed, and pressure; 3. High-resolution sensors and weighing display instruments are used for high weighing accuracy; 4. Key components are all imported and joint venture brands, stable and reliable; 5. Open Chinese and English human-machine interface, multi-area display and monitoring functions during system operation, easy to operate; 6. Fieldbus working system (i.e., setting PLC substations), low energy consumption design; 7. Automatic detection of operating conditions, giving alarm location and suggesting solutions in case of abnormalities; 8. Easy to maintain and repair, with safety interlocking protection measures to ensure safety; 9. Optimized dust removal and recovery system design, no dust flying or leakage, good operating environment, no raw material waste; 10. The rubber mixing engineering information management system integrates the latest information technology with production management and rubber mixing technology; 11. Flexible system design for different factory building structures (3, 4 floors) and process routes.

The Mach high-intensity mixer (10,000 horsepower) auxiliary machine is A fully intelligent material (powder, granular, block, liquid, etc.) conveying, storage, metering, batching, and feeding system for the rubber industry, independently developed based on the introduction and absorption of advanced technologies from Germany and the UK. It can be used with various specifications of 25-650L mixers. It mainly consists of five parts: carbon black (white material) part, oil part, rubber part, dust removal part, and the entire rubber mixing control system. Among them, the entire rubber mixing control system combines the latest information technology with production management and rubber mixing technology, integrating the entire process control of rubber mixing production, production plan management, material management, and quality tracking management. It truly achieves integrated control and has its own software copyright; it plays an important role in improving management level, improving product quality, and maintaining product stability. After years of continuous technological innovation and improvement by our company, this system has been widely used in the rubber tire, rubber products, rubber hose and belt, wire and cable, and rubber miscellaneous parts industries, and has been well received by customers at home and abroad.

Features:

1. Full-process control, monitoring, and recording of rubber mixing, enabling remote monitoring and after-sales support, improving management level;

2. Optimized mixing is achieved through integral calculation and logical control of parameters such as time, temperature, energy, speed, and pressure;

3. High-resolution sensors and weighing display instruments are used for high weighing accuracy;

4. Key components are all imported or joint venture brands, stable and reliable;

5. Open Chinese and English human-machine interface, multi-area display and monitoring functions during system operation, easy to operate;

6. Fieldbus working system (i.e., setting PLC substations), low energy consumption design;

7. Automatically detects the operating status and gives an alarm location and suggests solutions when abnormalities occur;

8. Easy to repair and maintain, with safety interlocking protection measures to ensure safety;

9. Optimized dust removal and recovery system design, no dust flying or leakage, good operating environment, no raw material waste;

10. The rubber mixing engineering information management system combines the latest information technology with production management and rubber mixing technology;

11. System design is flexible, tailored to different factory building structures (3 or 4 floors) and process routes.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn