Refractory Material Automatic Batching: What are the system advantages of automatic batching of refractory materials?

Published Time:

2021-12-17

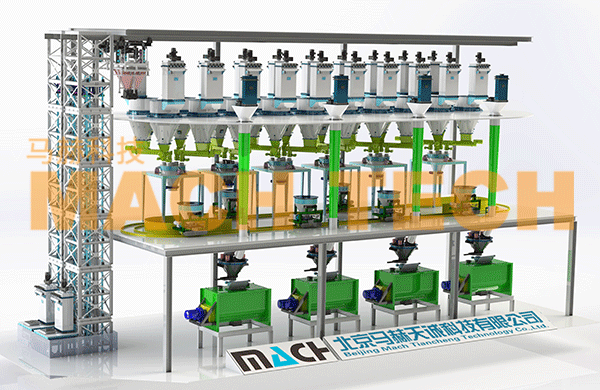

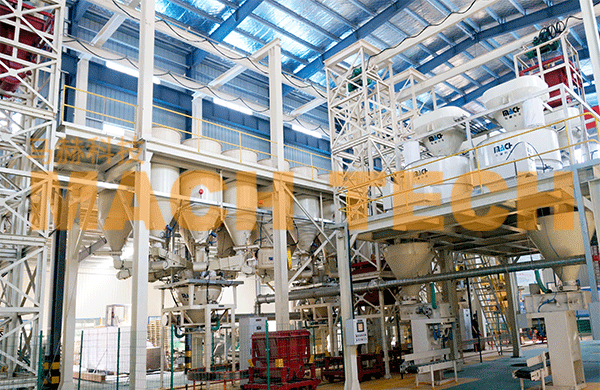

Refractory automatic batching is a material system used for automation in industrial production. It typically uses a computer with automatic material algorithm software as the control system for automatic material dispensing. The automated material system can simultaneously control multiple balances, various materials, or control output operations intuitively and clearly, with an automatic repair function. It is capable of recording large amounts of various types of data and table printing, and has a powerful reporting function with good stability. A powerful alarm notification function with online automatic monitoring can minimize the defect rate, allowing you to monitor important information in production at any time via a real-time online display.

Automatic Batching of Refractory Materials This is an automated material system used in industrial production. It typically uses a computer with automated material algorithm software as the control system. The automated material system can simultaneously control multiple balances, various materials, or control output operations intuitively and clearly, with an automatic repair function. It is capable of recording large amounts of various types of data and table printing, with a powerful reporting function and good stability. A powerful alert notification function and online automatic monitoring minimize waste, allowing you to monitor important information in production at any time via a real-time online display.

Automatic batching of refractory materials can be used for automated material handling in metallurgical production lines, cement production lines, rubber production lines, mixing stations, compound fertilizer production lines, etc.

What are the system advantages of automatic batching of refractory materials?

1: The automated material system is based on a programmable logic controller (PLC), featuring small size, high precision, and stable performance.

2: The automated material system can simultaneously control multiple scales, multiple materials, or control output (depending on the process).

3: Intelligent control of material time, with no waiting between material scales, shortening the material cycle, and improving material speed and output.

4: The automatic batching system uses a new WINXP system platform, displaying the production process through a faster, more stable, real-time, and dynamic production screen, which is intuitive, clear, and features an automatic recovery function.

5: The automated material system has a powerful reporting function, storing various types of data and table printing. A material report is automatically printed after each production, providing the date, time, report number, actual consumption of each item, etc. Report extraction uses a manual PC query method, saving the end-of-production report to the computer's internal storage, allowing unlimited reading to ensure the accuracy and completeness of the production report.

6: Simple operation; the system has three production modes: manual, semi-automatic, and fully automatic.

7: The PLC has strong data processing capabilities, a fast and stable sampling rate, and the material process fully meets process requirements.

8: The automatic batching system flow can be customized according to user settings.

9: High reliability. The automated material system has two control schemes (touch screen and industrial computer scheme). When one fails, the other will not immediately affect operation, preventing production failures and eliminating uncontrolled production phenomena.

10: The automated material system displays the production process and text in real-time graphics for easy operator operation.

11: The automatic batching system displays production reports, formula reports, etc., in text files (user selectable multiple printing options) with a powerful warning prompt function to minimize the scrap rate.

12: The automated material system ensures uniformity. Each aggregate uses a variable frequency drive to control the discharge speed, placing each aggregate within the same time frame to ensure material uniformity.

13: Automated material system online automatic monitoring: The relationship between humans and the production line changes from passive to active. Once an abnormality occurs in production, the computer system immediately alerts relevant personnel, proactively providing notification functionality and allowing real-time monitoring of important production information via a real-time online display.

Founded in 1996, Beijing Maher Tiancheng Technology Co., Ltd. is dedicated to the research and development and manufacturing of intelligent, green, and user-friendly intelligent equipment. The company focuses on the rubber, cable polymer materials, silicone, plastics, railway, friction materials, building materials, and footwear industries, providing global customers with customized non-standard products and supporting services, including intelligent and environmentally friendly automatic batching systems, silicone automatic batching, auxiliary machines (internal mixers, high-power kneaders), PVC centralized feeding, intelligent three-dimensional warehouses, intelligent logistics conveying systems, industrial information management control software, green environmental protection equipment, and automatic detection and packaging systems. If you have any needs in this area, please feel free to contact us.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn