Refractory Material Automatic Batching: Benefits of Intelligent Batching Control System

Published Time:

2022-02-24

Refractory material automatic batching manufacturers will tell you about the benefits of intelligent batching control systems and how intelligent batching control systems improve enterprise production efficiency and production environment. In various production fields such as chemical industry, metallurgy, building materials, pharmaceuticals, grain, feed, and food, the batching process is a very important link in the production process, which has a significant impact on production output and quality. Traditional industrial batching systems are not completely intelligent, informational, and automated, and there are many problems:

Refractory Material Automatic Batching The manufacturer will explain the benefits of the intelligent batching control system

How does the intelligent batching control system improve a company's high production efficiency and production environment?

In various production fields such as chemical engineering, metallurgy, building materials, pharmaceuticals, grains, feed, and food, the batching process is a crucial part of production, significantly impacting production output and quality. Traditional industrial batching systems are not entirely intelligent, informational, or automated, leading to numerous issues:

1. Batching speed and accuracy cannot meet production requirements;

2. Cannot meet the control requirements of various materials;

3. Cannot meet the requirements of formula conversion and adjustment;

4. Materials may be affected by ambient temperature and humidity;

5. Field production is dusty and the environment is harsh;

6. Information transmission is not timely, leading to management and production failures.

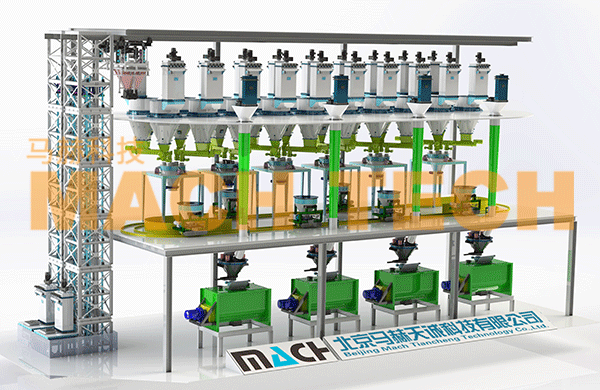

In the face of numerous challenges, traditional industrial batching methods can no longer meet the production needs of enterprises, affecting production efficiency and quality. Intelligent batching control systems have become a pressing issue for many manufacturing companies. Intelligent batching control systems are based on customer material characteristics, formulas, and production processes, using belts or batching screws as conveying tools. They can complete batching control of bulk materials and various data management during the production process according to user requirements. This system is an integrated system combining hardware and software, basic production, and management, helping companies achieve the goals of improving production efficiency, optimizing the production environment, reducing costs, and strengthening scientific management.

Faced with complex and variable formulas and various material ratios, the intelligent batching control system can flexibly adjust the ratios of various materials according to the customer's actual formula and production process. Customers only need to set parameters on the host computer. Given the harsh, dusty, and variable environment, materials may be affected by temperature and humidity. The batching control system can select appropriate conveying and metering equipment, such as screw feeders and belt conveyors, according to the material. It can also add sealed structures. On the one hand, it can improve and optimize the production environment; on the other hand, it can prevent material dropping and waste, while also protecting the materials.

The intelligent batching control system can not only solve the problem of difficult batching control in on-site production but also develop software management systems. The system's measurement and control data is uploaded and displayed in real-time to relevant management departments, generating visualized data reports. Managers can remotely monitor production, and scientific production scheduling decisions have strong data support. In addition, to protect data security, the system can set different levels of operating permissions to prevent human fraud and protect the company's production data.

Refractory Material Automatic Batching That's all for today's introduction from the manufacturer. Thank you for watching, and see you next time.

Beijing Maher Tiancheng Technology Co., Ltd., established in 1996, provides global customers with customized non-standard products and supporting services, including auxiliary machinery (internal mixer, high-power kneader), PVC centralized feeding, refractory material automatic batching, magnetic material automatic batching, and silicone automatic batching. The company is committed to the research and development and manufacturing of intelligent, green, and user-friendly intelligent equipment. The company is based in the rubber, cable polymer materials, silicone, plastics, railway, friction materials, building materials, and footwear industries. Our company always adheres to the guiding ideology of "customer-centric and long-term operation," being honest and trustworthy, keeping promises, ensuring user satisfaction, and innovating together. If you have any needs in this area, please feel free to contact us for consultation.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn