Walk - Take you to explore the unusual aspects of Mach auxiliary machines 1 - New era, new applications

Published Time:

2022-04-04

Rubber mixing production is centered around main machines such as internal mixers or kneaders. Various formula materials are automatically fed into the main machine according to the rubber mixing process through storage, conveying, buffering, weighing, and feeding equipment. The equipment used in this process is called auxiliary equipment;

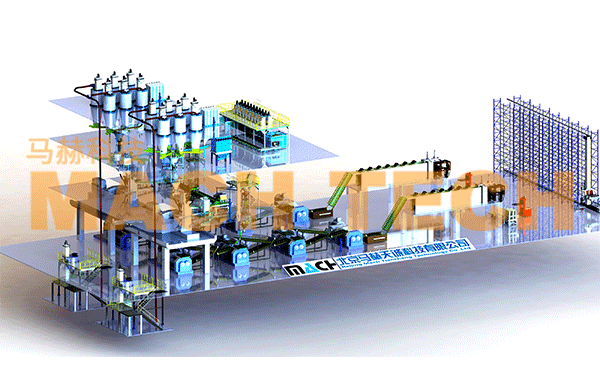

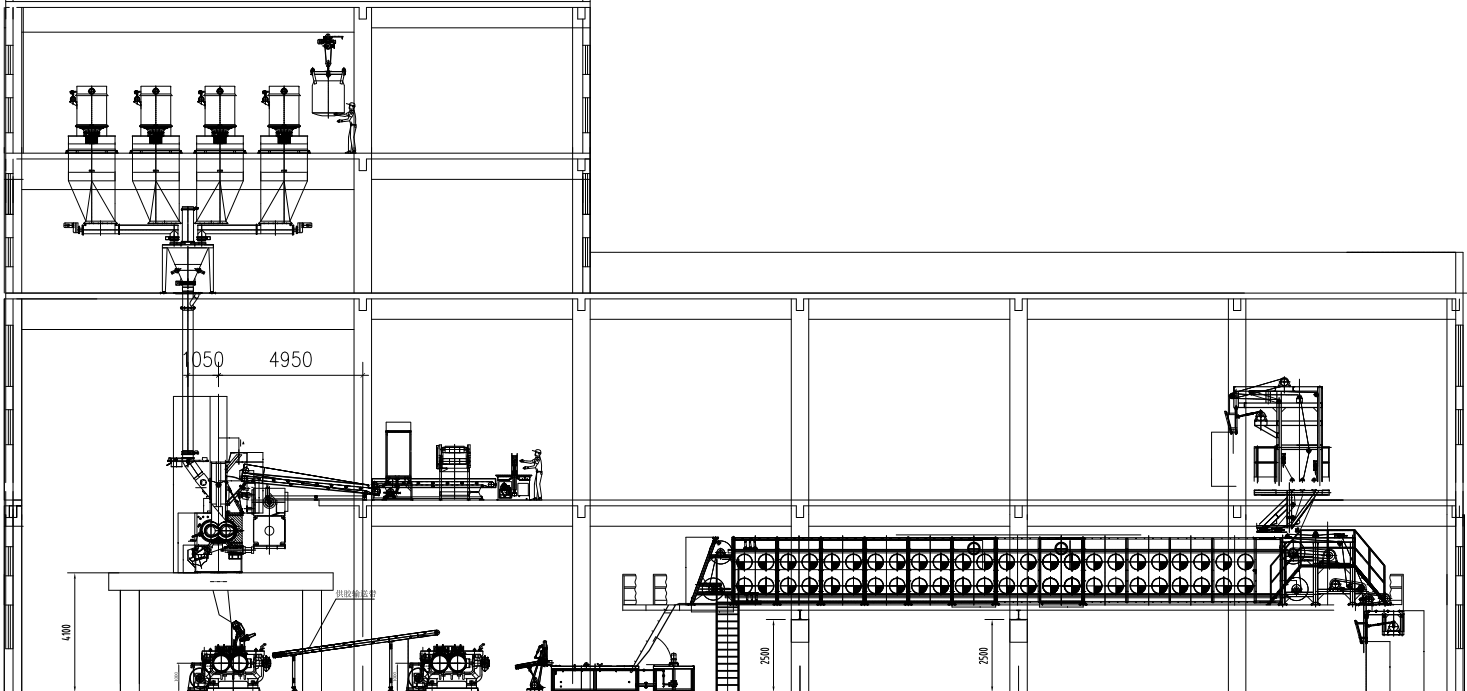

After mixing, the rubber is discharged from the main machine and enters the rubber conveying press and rubber sheet cooling stacking device. These post-processing devices are called downstream auxiliary equipment. The upstream auxiliary equipment, internal mixer, and downstream auxiliary equipment constitute a rubber mixing production line, which is interconnected and controlled by the intelligent rubber mixing control system V1.0 for fully automatic continuous production.

The materials used in rubber product manufacturing are numerous and varied in form and quantity. Some compounding agents are easily scattered, harming workers' health. Manual operations are labor-intensive, with poor hygiene conditions and no environmental protection. The work efficiency is low, the weighing error is large, the error rate is high, the effective utilization time of the internal mixer is relatively reduced, the energy consumption is high, and it cannot meet the increasing demand for the quality and uniformity of rubber products. Mistakes made during periods of backward technology and equipment, such as incorrect feeding, weighing errors, low efficiency, and high comprehensive costs, cannot be compensated for in subsequent processing.

This is the current situation, while previously it was.......

This is how it used to be--wasn't it intense?

The development and application of upstream auxiliary equipment have greatly avoided these shortcomings. As the first process, i.e., automatic raw material conveying and batching, upstream auxiliary equipment plays an indispensable key role in intelligent rubber mixing production. Based on the introduction and absorption of advanced technologies from Germany and the UK, Maher upstream auxiliary equipment is an independently developed fully intelligent material (powder, granular, block, liquid, etc.) conveying, storage, metering, batching, and feeding system for the rubber and plastics industries. It can be used with various specifications of internal mixers / High-power/tipping Kneader/high-mixer/kneader matching. Maher Upstream auxiliary equipment is a system integration, It mainly consists of five parts: powder part, liquid part, block part, dust removal part, and the whole process control system. Its technical core - the whole process control system - combines the latest information technology with production management and production processes, integrating production process control, production plan management, material management, and quality tracking management into one, truly achieving integrated control; improving management level, improving product quality, and maintaining product stability. After nearly 20 years of continuous technological accumulation, innovation, and improvement by our company, this system has been put into practical application by more than 600 customers and exported to 15 countries and regions.

Intelligent and environmentally friendly rubber mixing production line system flowchart

So, what are the unique features of Maher upstream auxiliary equipment? Further details will be explained later......

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn