Walk - Take you to explore what unusual features the Mach upper auxiliary machine has - Core central control software

Published Time:

2022-04-22

The upper auxiliary machine system is complex and large. In addition to the various physical devices and components mentioned above, powerful automatic control and information technology are its core. Intelligent control technology and the external factors of green development, as well as independent innovation and research and development, have enabled Mach's upper auxiliary machine information management and control technology to maintain a leading position in the industry.

The auxiliary machine system is complex and large. In addition to the various physical devices and components mentioned above, powerful automatic control and information technology are its core, and are the key factors determining the stability, accuracy, and automation level of the auxiliary machine system.

Intelligent control technology and the development of external factors such as greening, as well as independent innovation and research and development, have enabled Maher's auxiliary machine information management and control technology to maintain a leading position in the industry.

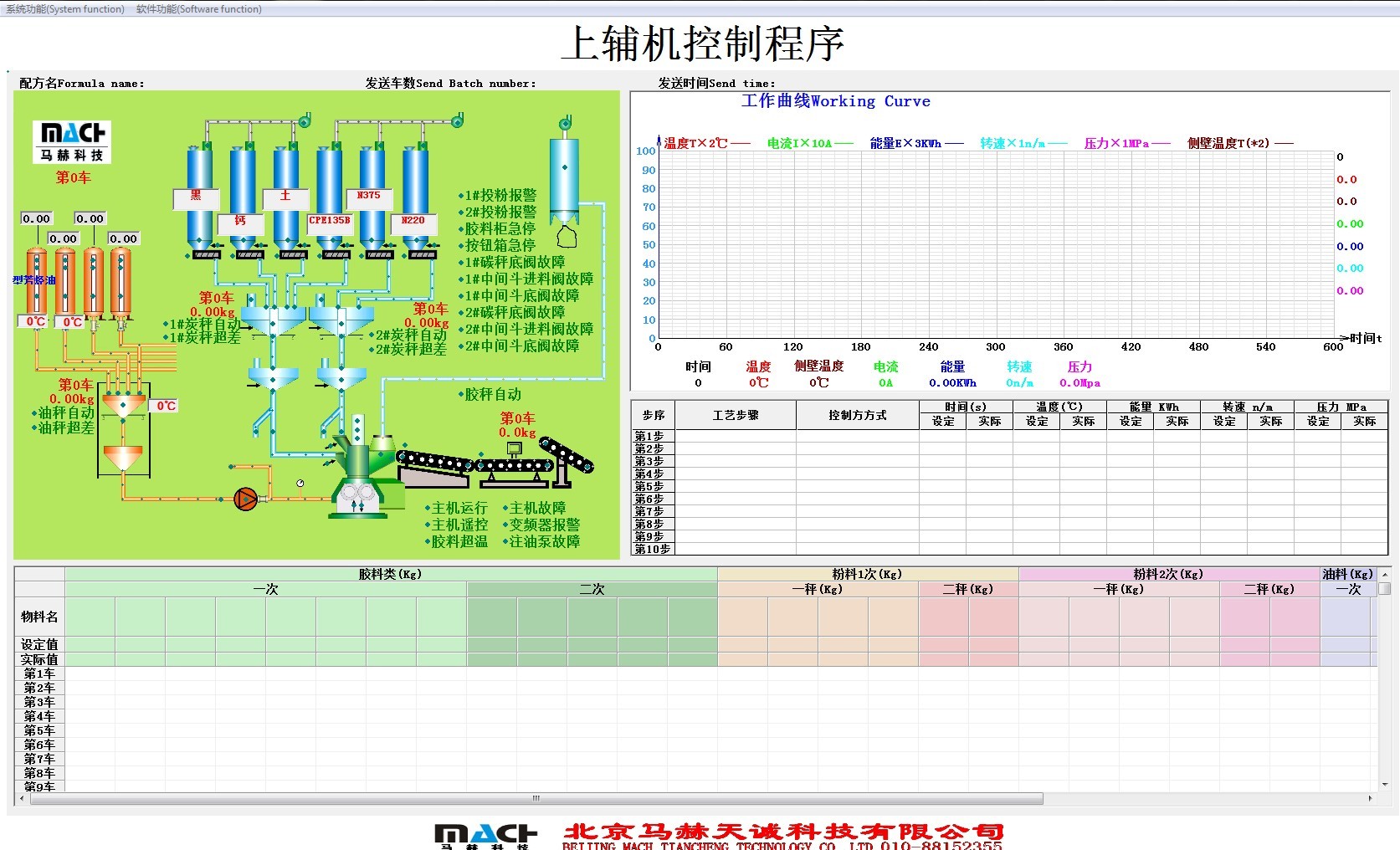

The control system is a two-level computer control system, with a host computer in the control room, The lower-level computer uses a programmable controller It uses a fieldbus working system to form real-time dynamic monitoring and management of the weighing and mixing system production process. The software part is the core of the auxiliary machine control system. It automatically controls carbon black conveying, raw material weighing, feeding, and mixing, and has functions such as recipe management and report printing.

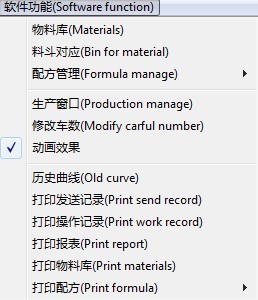

a Recipe Management: The system can command various actuators to feed the required materials into the mixer at a specified time and quantity according to different recipe requirements.

Recipe management completes the input, modification, storage, and display of recipes. The recipe management design is flexible and can adapt to any mixing process.

b Production Window: Production plans can be added, inserted, modified, deleted, and imported, production tasks can be sent, and tasks can be saved.

c Operation Monitoring: Simulates the dynamic process screen of the mixing system production process, from the daily material bin and storage tank to the mixer. Allows operators to intuitively and promptly understand the current status of the production process flow on the display screen. The computer monitors the running status of the auxiliary machine system and extracts various operating data from the PLC. In the monitoring window, you can see the weighing status of each scale and the working status of the mixer, including which step the mixer has reached, the current mixing temperature, power, etc. In addition, the monitoring window also shows whether the equipment has an alarm. This monitoring can be switched from the foreground to the background production monitoring dynamic screen.

d Curve Monitoring: The computer monitors the temperature, power, speed, and upper top bolt pressure signals of the mixer in real time and displays their change curves on the screen. The mixer needs to provide relevant signals.

e Optimized Mixing Function: The data management system of the automatic control system collects the process temperature curve, power trend curve, and upper top bolt pressure curve during mixing production to reflect the changes in the monitored quantities in real time. It has a "and", "or" relational combination control mixing method with three parameters of time, energy (power), and temperature. Optimized mixing is achieved through control of the trend curve.

f Alarm Function: To ensure the reliability of automatic mixing, the system has an incomplete control function. The system automatically detects the temperature, pressure, weight, and other data of each monitoring point. When an abnormality occurs, an audible and visual alarm and screen display alarm are given, and the detailed alarm content can be automatically recorded and printed. If a step is found to be incomplete, an alarm is issued, and after manual processing, the next step can be continued.

g: The computer has a network interface and can communicate and interact with the factory MES (Manufacturing Execution System) system data. It can realize office networking, remote monitoring, and after-sales support. New management functions can be added according to user needs.

h: Auxiliary functions: It has fault self-diagnosis, prompt, and recording functions; automatically stores the status, trend curves, alarms, etc. of the monitored quantities at different times in files for future reference, providing a basis for functional departments to conduct production and quality management.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn