Automatic batching and preparation method and process of magnetic materials

Published Time:

2022-07-27

Magnetic material automatic batching replaces manual automatic raw materials. The raw materials for nitrile rubber foaming are numerous and varied, including powder and granular forms. Each formula change requires special recording for future reference. Manual work is labor-intensive and requires improvement of existing technology. The following describes the preparation method and process of automatic batching of magnetic materials.

In the traditional preparation process of nitrile rubber foam materials, various raw materials need to be formulated in a certain proportion. Traditional nitrile rubber foam materials mostly use manual material preparation, which is complex and inefficient. With the development of science and technology, magnetic material automatic batching has replaced manual automatic material preparation. Nitrile rubber foam raw materials are numerous and varied, including powder and granular materials. Each formula change needs to be specially recorded for reference. Manual work is labor-intensive and requires improvement of existing technology. The above technical problems have been solved. Let's learn about the preparation method and process of magnetic material automatic batching!

The specific steps of magnetic material automatic batching include:

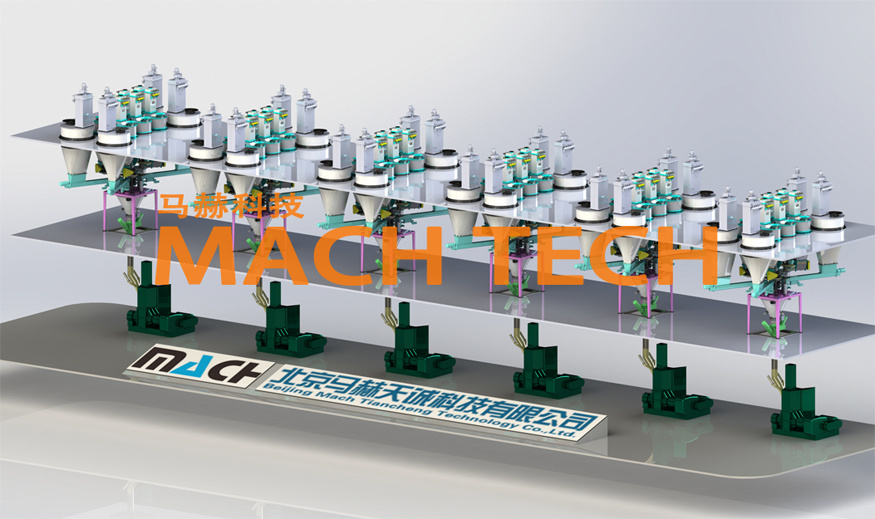

In magnetic material automatic batching, the raw materials used to manufacture nitrile rubber foam materials are added one by one to the negative pressure conveying mechanism. Under the action of negative pressure, the raw materials in the negative pressure conveying mechanism are transported to the feed pipe through the feed pipe; the feed pipe is connected to each hopper, and a switch valve is installed on the feed pipe. The opening and closing of the feed pipe is controlled by controlling the opening and closing of the switch valve through the PLC controller; by controlling the opening and closing of the switch valve through the PLC controller, various raw materials are sent to the designated hopper for storage one by one; the opening of the hopper's lower discharge plate is controlled by the PLC controller to input the discharged raw materials into the hopper, and the discharging auxiliary device transports the discharged materials to the designated material tank; the raw material barrels are placed one by one on the conveying mechanism, and before the conveying mechanism transports the raw material barrels to the material feeding auxiliary device at the hopper position for storing the specified raw materials.

The action of the telescopic mechanism under the raw material barrel is controlled by the PLC controller to make the weighing device move upward, and the tray on the weighing device lifts the entire raw material barrel; the weighing device weighs when the feeding auxiliary device is added to the raw material barrel. A positioning device is fixedly installed on the weighing device to control the stop of the conveying mechanism and complete the positioning stop of the raw material barrel; after a raw material is put into the raw material tank with the specified matching weight, the telescopic mechanism retracts, and the conveying mechanism continues to transport the raw material tank to the hopper position where the other raw material is stored. The operation of repeatedly extending and retracting the telescopic mechanism completes the addition of materials to the raw material tank; after the raw materials are added to the raw material tank one by one, the transportation mechanism moves the raw material tank to the unloading area; in this invention, the material feeding auxiliary device is divided into a belt conveyor and a screw conveyor. The belt conveyor is used for adding powder raw materials, and the screw conveyor is used for adding granular raw materials.

Magnetic material automatic batching can realize automatic batching of nitrile rubber foam raw materials. In addition, the setting of multiple hoppers in this device allows different raw materials to be added to the same hopper as needed to meet the needs of multiple raw materials, and the addition of raw materials in this process is realized through a PLC controller, with high automation and high automation. This invention is an automatic batching process, which specifically includes the following steps:

1. Add the raw materials used to manufacture nitrile rubber foam materials one by one to the negative pressure conveying mechanism. Under the action of negative pressure, the raw materials in the negative pressure conveying mechanism are transported to the feed pipe through the feed pipe; the feed pipe is connected to each hopper, and a switch valve is installed on the feed pipe. The opening and closing of the feed pipe is controlled by controlling the opening and closing of the switch valve through the PLC controller; by controlling the opening and closing of the switch valve through the PLC controller, various raw materials are sent to the designated hopper for storage one by one. The raw materials stored in the hopper are powder and granular materials.

2. Use the PLC controller to control the opening of the lower discharge plate of the hopper, input the batching used during discharging into the hopper, and use the discharging auxiliary device to transport the batching to the designated batching tank. The feeding auxiliary device is divided into a belt conveyor and a screw conveyor. The belt conveyor is used to transport powder raw materials, and the screw conveyor is used to transport granular raw materials.

3. Raw material barrels are placed one by one in the conveying mechanism, and the conveying mechanism transports the raw material barrels to the hopper position where the specified raw materials are stored.

4. Before the discharging auxiliary device discharges, use the PLC controller to control the action of the telescopic mechanism below the discharging tank, so that the weighing device rises, and the tray on the weighing device lifts the entire discharging tank; the weighing device weighs when the feeding auxiliary device is added to the raw material tank. A positioning device is also fixedly installed on the weighing device to control the stop of the conveying mechanism and complete the positioning stop of the raw material tank.

5. After the raw materials are put into the raw material tank with the specified matching weight, the telescopic mechanism retracts, and the conveying mechanism continues to transport the raw material tank to the hopper position where other raw materials are stored. The operation of repeatedly extending and retracting the telescopic mechanism completes the addition of materials to the raw material tank; each time raw materials are added to the raw material tank, the transportation mechanism moves the raw material tank to the unloading area.

The above is an introduction to the preparation method and process of magnetic material automatic batching. If you need to know more, please feel free to contact us!

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn