How about automatic batching of magnetic materials?

Published Time:

2022-07-11

Referring to the weight of the fabric tube and the thickness of the knitted fabric, the liquid rate of all knitted fabrics is set to a certain value by default. In the actual production process, the volume of chemical raw materials is excessive, leading to the cost of COD (wastewater treatment). So, let's learn about the automatic batching of magnetic materials!

In the textile field, the liquid retention rate of different knitted fabric names during processing in finishing plants has always been a vague concept, thus causing the following problems in production. When estimating the volume of chemical raw material liquid, planners refer to the weight of the material cylinder and the thickness of the knitted fabric, setting the liquid retention rate of all knitted fabrics to a certain value by default. In actual production, the volume of chemical raw material liquid is excessive, leading to increased COD (wastewater treatment) costs. So, let's learn about automatic batching of magnetic materials!

Essential Elements for Automatic Batching of Magnetic Materials:

Automatic batching of magnetic materials requires an automatic batching system that can save chemical materials and reduce wastewater treatment costs.

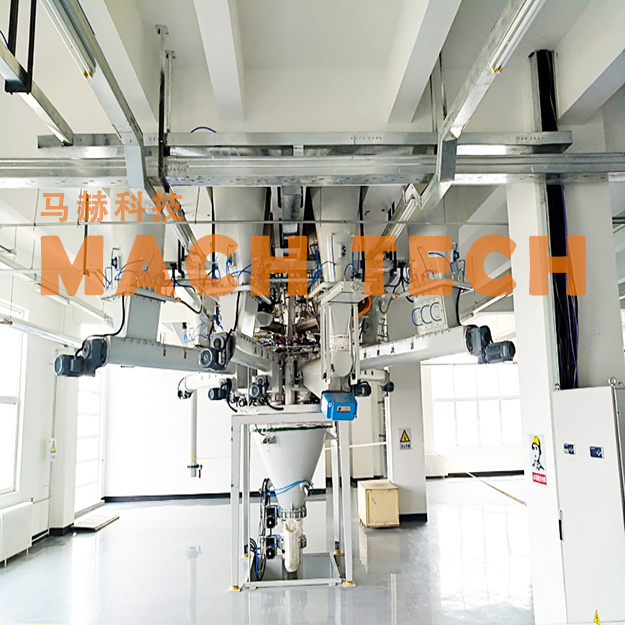

The automatic batching system for magnetic materials includes:

A raw material mechanism, which is connected to the raw material elements and is used to automatically supply the raw material elements to the raw material cylinder; the control unit includes: a weighing mechanism connected to the weighing unit to obtain the weight change value per unit time of the fabric; the control mechanism is connected to the liquid level measuring element to obtain the liquid level change value;

A measuring unit, which is connected to the liquid level measuring element installed in the tank to measure the liquid level change value per unit time of the liquid in the tank and obtain the liquid level change value;

The automatic batching system for magnetic materials can obtain the corresponding liquid retention rate of the fabric based on the above-mentioned liquid level change value corresponding to the above-mentioned weight change value of each fabric, obtain the raw material coefficient of each fabric based on the liquid retention rate of each fabric, and obtain the corresponding raw material data of the fabric based on the raw material volume formula. That is, when increasing the pressure of the next fabric for the corresponding fabric, the raw material coefficient corresponding to the weight of the raw material fabric can be multiplied, so that the required amount of chemical raw material liquid can be correctly obtained, and it will not become an excessive amount of chemical raw material liquid. This automatic batching system helps save water, save the DCA cost of the finishing plant, reduce wastewater discharge from the finishing plant, and reduce COD treatment costs.

The automatic batching system for magnetic materials solves the problem of weighing accuracy of chemical materials by debugging 20 kinds of chemical materials and controlling the weighing of each chemical material. By testing and verifying the liquid retention rate of different fabrics through the automatic batching system, a dictionary table of different fabrics can be compiled, which facilitates later direct query of materials and saves time. The automatic batching system accurately controls the batching volume, reduces wastewater discharge from the finishing plant, and reduces COD treatment costs.

The above is an introduction to the automatic batching of magnetic materials. If you need to know more, please feel free to contact us!

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn