Introduction to the advantages of automatic plastic and resin batching

Published Time:

2023-03-21

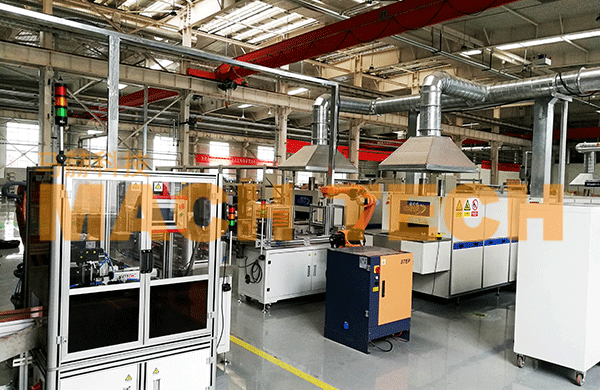

Automatic batching of plastics is widely used in industrial production and daily life. Automatic batching systems have brought great convenience and advantages to the plastics processing industry. Automatic batching systems are gradually replacing traditional manual operation and inspection in the production and processing of plastics, because automatic batching systems have multiple advantages.

Automatic batching of plastics and resins is widely used in industrial production and daily life. Automatic batching systems bring significant convenience and advantages to the plastics processing industry. In plastics production and processing, automatic batching systems are gradually replacing traditional manual operation and inspection due to their multiple advantages.

Improved Production Efficiency

Automatic batching systems can accurately calculate and batch materials, significantly improving production efficiency. In the production process, human factors can easily lead to calculation errors, a problem solved by automatic batching systems, increasing production speed and accuracy.

Cost Savings

Automatic batching systems accurately control material usage, enabling waste-free production and effectively saving production costs. Furthermore, due to the high efficiency of automatic batching systems, the same amount of production can be completed in less time, significantly saving companies on labor and energy costs.

Reduced Product Defects

Calculation errors and human factors during manual batching can lead to high product defect rates. Automatic batching systems, with their high-precision measurement capabilities, effectively avoid these problems, compensating for the shortcomings of manual batching.

Improved Working Conditions

Automatic batching systems are superior to manual operation in monitoring dust, eliminating odor, and reducing environmental pollution, improving working conditions and protecting employee health.

Enhanced Industry Competitiveness

In a highly competitive environment, automatic batching systems can improve a company's production efficiency, product quality, and reduce costs, further enhancing industry competitiveness and development potential.

Environmental Compliance

Automatic batching systems do not produce large amounts of waste and dust during production, effectively reducing pollutant emissions and meeting the environmental requirements of modern industry. Additionally, the materials used in automatic batching systems can be reused, also benefiting the environment.

In summary, automatic batching systems for plastics and resins offer irreplaceable advantages in production efficiency, cost reduction, and environmental protection, bringing significant opportunities and contributions to the plastics processing industry.

With the continuous development of technology, automation technology has been widely used in various industries, and automatic batching of plastics and resins is no exception. Automatic batching not only improves production efficiency but also avoids interference from human factors, improving product quality. However, the following points should be noted when using automatic batching:

Raw Material Storage

Raw materials for automatic batching often require long-term storage; therefore, the storage environment should be dry, free of water, dust, and odor. At the same time, storage should strictly follow storage requirements to avoid affecting raw material quality.

Conveying Method

During raw material conveying, dust-free and sterile conveying methods should be used to prevent raw materials from being contaminated or deteriorating.

Batching Accuracy

The accuracy of the automatic batching system plays a key role in product quality. Therefore, when using automatic batching, appropriate batching accuracy should be set according to the different properties, viscosity, and particle size of the raw materials to ensure product quality.

Maintenance

Automatic batching systems require long-term operation; therefore, regular maintenance and inspection are necessary during use to check whether the circuits, pneumatic systems, and transmission components are operating normally, ensuring the normal operation of the equipment.

In short, when using an automatic batching system for plastics and resins, attention must be paid to detail, and all aspects of preparation and maintenance must be done well to ensure the accuracy of batching and product quality.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn