Introduction to the uses of automatic plastic and plastic material dispensing

Published Time:

2023-04-06

Plastic processing is a crucial part of modern industry. Precise material weighing is key to successful plastic processing production. Traditional manual weighing methods are not only inefficient but also prone to errors, resulting in production losses. Therefore, automatic plastic material weighing technology has emerged. It mainly achieves precise material weighing through automatic weighing machines and control systems, improving production efficiency and product quality. This article will detail the uses of automatic plastic material weighing.

Plastic processing is a crucial part of modern industry. Accurate batching is key to successful plastic processing production. Traditional manual weighing methods are not only inefficient but also prone to errors, resulting in production losses. Therefore, automatic batching technology for plastics and resins has emerged. It mainly uses automatic batching machines and control systems to achieve accurate batching, improving production efficiency and product quality. This article will detail the uses of automatic batching of plastics and resins.

Improve Product Quality

Automatic batching eliminates the influence of human factors, making batching more accurate. At the same time, the weighing system of the automatic batching machine has high precision, can control the batching ratio, and reduce material waste and product quality problems.

Achieve Intelligent Production in Conjunction with the Production Line

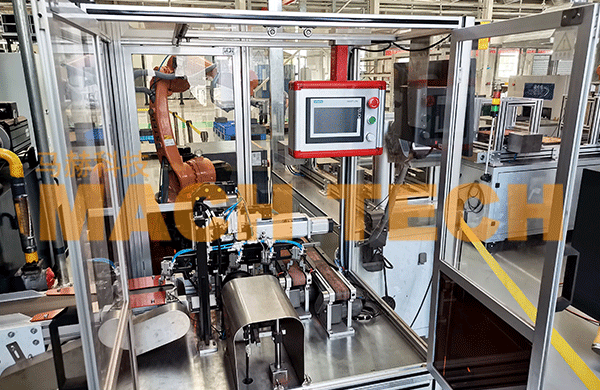

Automatic batching machines can be integrated into existing production lines to achieve automated production. In addition, automatic batching machines can be connected to the control system to adjust production parameters and equipment through real-time monitoring.

Improve Production Efficiency

Compared with manual weighing, automated batching can significantly improve production efficiency. The fast and accurate batching speed can shorten the production cycle and reduce the time and cost of manual batching.

Optimize Raw Material Inventory Control

The automated production process can accurately control raw material consumption according to market demand and production plans. At the same time, by monitoring the raw material inventory, the automatic batching machine can achieve fixed-point replenishment of raw materials, reducing economic losses caused by inventory backlog.

Reduce Operating Costs

The initial cost of automated batching equipment is high, but it can bring higher production efficiency and quality to the enterprise. With the increase in production volume, the automatic batching machine gradually becomes an essential item for enterprises. At the same time, the automatic batching machine can reduce labor costs and human resource investment.

In short, automatic batching technology can save manpower, enhance productivity, and improve product quality for plastics and resins processing enterprises. It is an important part of modern production methods.

Automatic batching of plastics and resins, as the name suggests, is a technology that automatically handles the batching of plastic raw materials. Through automated methods of measurement, transportation, and mixing, the plastic raw materials achieve the specified component ratio and are accurately mixed and stirred, ultimately achieving the goal of automated production process integration. So, what is the principle of this technology? Let's analyze it together below.

Automatic Measurement Principle

Automatic measurement is a technology that uses digital signals detected by digital sensors to achieve the measurement of plastic raw materials. Through this technology, automatic measurement of plastic raw materials can be achieved, and the required parts of the raw materials are automatically proportioned according to a certain ratio.

Conveying System Principle

The conveying system is the process of conveying various plastic raw materials from the material warehouse to the mixer. It mainly includes material conveying systems, pneumatic conveying systems, vacuum suction conveying systems, etc. Through the conveying system, various plastic raw materials can be automatically conveyed to the mixer.

Computer Control Principle

The computer control principle is an important link in the automatic batching of plastics and resins. It mainly uses an automated control system to control the entire batching process. Computer control effectively improves the accuracy of the ratio.

Mixing and Stirring Principle

Mixing and stirring is the process of mixing and stirring different plastic raw materials in a mixer to ensure that various plastic raw materials are mixed evenly. The mixing and stirring process is achieved by controlling the stirring speed, time, and method to ensure that the plastic raw materials are mixed evenly.

Automatic Cleaning Principle

Automatic cleaning is the process of automatically cleaning the remaining materials after mixing is completed. It mainly uses vibration cleaning, air knife scrapers, etc., for cleaning.

In short, the automatic batching technology of plastics and resins relies on these principles and achieves effective automated batching of plastic raw materials through a series of automated processes such as measurement, conveying, mixing, and stirring.

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn