- Product Description

-

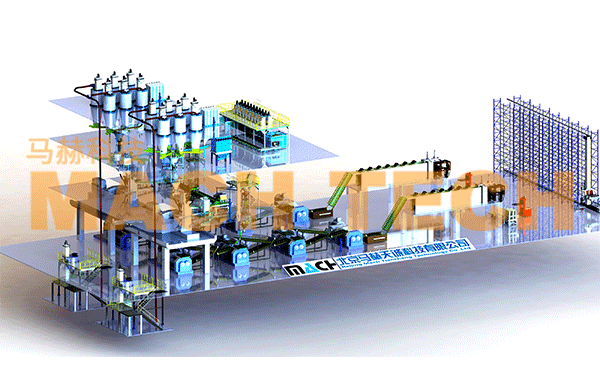

This system is mainly suitable for single-story factory buildings. Based on user requirements for precision, efficiency, and factory conditions, the large-material handling system is customized in various forms, such as negative pressure, negative pressure + three-dimensional, small three-dimensional, vertical screw, etc., to complete the batching and metering process. It meets the requirements of internal mixers/kneaders for the storage, conveying, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the internal mixer/kneader host. It is mainly used in the production of rubber, plastics, cable materials, food, pharmaceuticals, chemical raw materials, and other products.

Outstanding Advantages:

This system offers flexible process layout options, resulting in low factory investment costs;

Raw material storage and unpacking are separated from the production area, reducing the handling of large materials, thus saving energy and protecting the environment;

The unpacking device uses single-machine dust removal, resulting in no raw material loss;

It achieves automated production and information management, improving user management levels;

Mainly suitable for internal mixers and kneaders with specifications of 270 type and below, with a mixing cycle of 4-6 minutes, it offers high efficiency, high precision, uniform and stable product quality, and traceability;

Mach auxiliary equipment is independently researched and manufactured by Mach Technology, a leading enterprise in the rubber machinery industry, showcasing intelligent, green, and user-friendly leading technology.

A strong R&D team of nearly 90 people ensures reliable product quality and stable operation, earning the trust and recommendation of nearly 700 users at home and abroad.

Auxiliary equipment for kneading machines/mixing mills (single-story factory building, customized negative pressure + three-dimensional, small three-dimensional, vertical spiral conveying, large material offline solutions, etc.)

- Product Description

-

This system is mainly suitable for single-story factory buildings. Based on user requirements for precision, efficiency, and factory conditions, the large-material handling system is customized in various forms, such as negative pressure, negative pressure + three-dimensional, small three-dimensional, vertical screw, etc., to complete the batching and metering process. It meets the requirements of internal mixers/kneaders for the storage, conveying, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the internal mixer/kneader host. It is mainly used in the production of rubber, plastics, cable materials, food, pharmaceuticals, chemical raw materials, and other products.

Outstanding Advantages:

This system offers flexible process layout options, resulting in low factory investment costs;

Raw material storage and unpacking are separated from the production area, reducing the handling of large materials, thus saving energy and protecting the environment;

The unpacking device uses single-machine dust removal, resulting in no raw material loss;

It achieves automated production and information management, improving user management levels;

Mainly suitable for internal mixers and kneaders with specifications of 270 type and below, with a mixing cycle of 4-6 minutes, it offers high efficiency, high precision, uniform and stable product quality, and traceability;

Mach auxiliary equipment is independently researched and manufactured by Mach Technology, a leading enterprise in the rubber machinery industry, showcasing intelligent, green, and user-friendly leading technology.

A strong R&D team of nearly 90 people ensures reliable product quality and stable operation, earning the trust and recommendation of nearly 700 users at home and abroad.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn