- Product Description

-

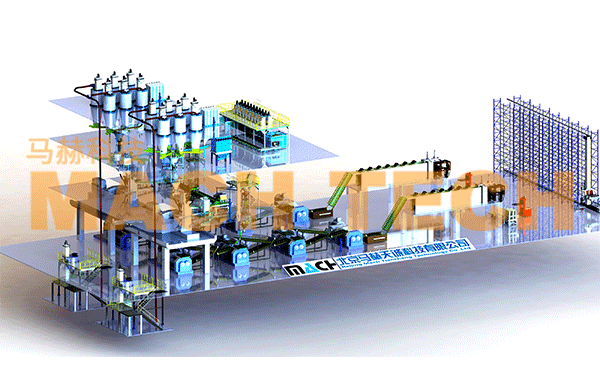

Introduction to Centralized Material Supply System

It is a material supply system used in industrial production. It achieves centralized management and efficient distribution of materials by transporting raw materials from a central storage area to multiple production equipment or workstations.

This system typically includes the following main components:

1. Storage tanks or silos: Used to store raw materials such as plastic granules, powders, and liquids.

2. Conveying equipment: Such as conveyor belts, screw conveyors, pneumatic conveyors, etc., used to transport materials from storage tanks to various production equipment.

3. Metering equipment: Used to accurately measure the supply of materials to ensure accurate material proportions in the production process.

4. Control system: Used to monitor and control the operation of the entire material supply system, including level or weight monitoring of storage tanks, start-stop control of conveying equipment, and adjustment of metering equipment.

The advantages of a centralized material supply system include:

1. Improve production efficiency: By centralizing management and automating material distribution, it can reduce manual operation time and material handling time, thereby improving production efficiency.

2. Ensure material quality: By accurately measuring and controlling the supply of materials, it can ensure accurate material proportions in the production process and guarantee product quality.

3. Reduce production costs: By centralizing management and automating material distribution, it can reduce manual operation costs and material handling costs, thereby reducing production costs.

4. Improve production safety: By centralizing management and automating material distribution, it can reduce safety risks during manual operations and improve production safety.

In summary, the centralized material supply system is an efficient, reliable, and safe material supply system that is of great significance to improving the efficiency and quality of production in the rubber and plastics industry.

Centralized feeding system & large warehouse automatic storage system

Keywords

- Product Description

-

Introduction to Centralized Material Supply System

It is a material supply system used in industrial production. It achieves centralized management and efficient distribution of materials by transporting raw materials from a central storage area to multiple production equipment or workstations.

This system typically includes the following main components:

1. Storage tanks or silos: Used to store raw materials such as plastic granules, powders, and liquids.

2. Conveying equipment: Such as conveyor belts, screw conveyors, pneumatic conveyors, etc., used to transport materials from storage tanks to various production equipment.

3. Metering equipment: Used to accurately measure the supply of materials to ensure accurate material proportions in the production process.

4. Control system: Used to monitor and control the operation of the entire material supply system, including level or weight monitoring of storage tanks, start-stop control of conveying equipment, and adjustment of metering equipment.

The advantages of a centralized material supply system include:

1. Improve production efficiency: By centralizing management and automating material distribution, it can reduce manual operation time and material handling time, thereby improving production efficiency.

2. Ensure material quality: By accurately measuring and controlling the supply of materials, it can ensure accurate material proportions in the production process and guarantee product quality.

3. Reduce production costs: By centralizing management and automating material distribution, it can reduce manual operation costs and material handling costs, thereby reducing production costs.

4. Improve production safety: By centralizing management and automating material distribution, it can reduce safety risks during manual operations and improve production safety.

In summary, the centralized material supply system is an efficient, reliable, and safe material supply system that is of great significance to improving the efficiency and quality of production in the rubber and plastics industry.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn