- Product Description

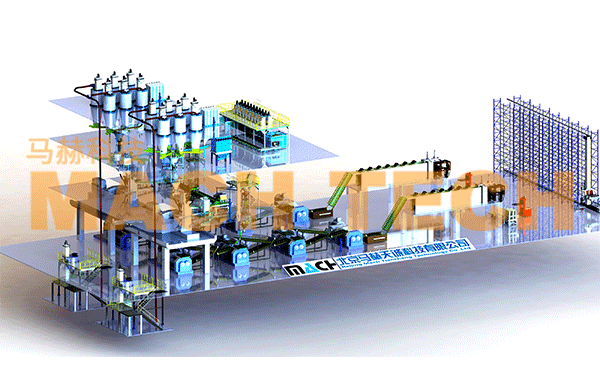

Intelligent three-dimensional warehouse

Category

Keywords

- Product Description

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn