- Product Description

-

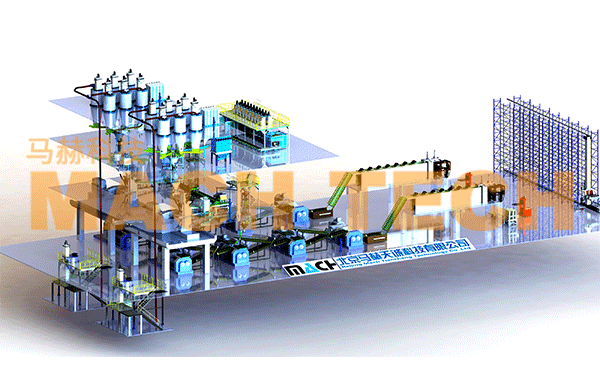

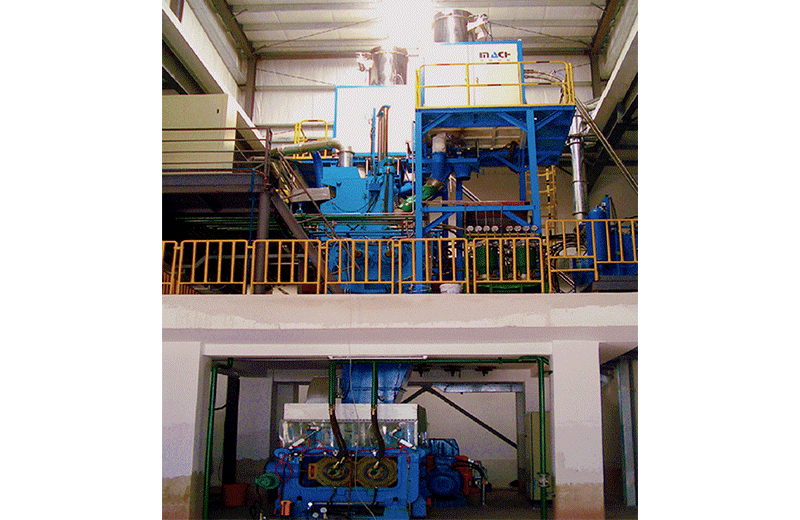

This system is mainly applicable to single-story and double-story factory buildings, where large materials are transported and metered using negative pressure suction. It meets the requirements of the main mixing mill/kneading mill for the storage, transportation, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the main mixing mill and kneading mill. It is mainly used in the production of rubber products, plastic products, cable materials, food, pharmaceuticals, chemical raw materials, and other products.

Main features:

This system has a flexible process layout, low factory investment cost, reduces the handling of large materials, separates raw material storage and unpacking from the production area, and maintains a clean environment; the unpacking device uses single-machine dust removal, with no raw material loss, and achieves automated production and information management. It is mainly suitable for mixing mills and kneading mills with specifications below 160. Because the batching cycle is slower than that of the three-dimensional auxiliary machine, the mixing cycle is generally required to be around 6 minutes. The effect is better when using granulated raw materials. Hygroscopic and astringent special materials need to be confirmed before use.

Auxiliary equipment for internal mixer/kneader (one or two-story factory building, large material negative pressure conveying method)

- Product Description

-

This system is mainly applicable to single-story and double-story factory buildings, where large materials are transported and metered using negative pressure suction. It meets the requirements of the main mixing mill/kneading mill for the storage, transportation, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the main mixing mill and kneading mill. It is mainly used in the production of rubber products, plastic products, cable materials, food, pharmaceuticals, chemical raw materials, and other products.

Main features:

This system has a flexible process layout, low factory investment cost, reduces the handling of large materials, separates raw material storage and unpacking from the production area, and maintains a clean environment; the unpacking device uses single-machine dust removal, with no raw material loss, and achieves automated production and information management. It is mainly suitable for mixing mills and kneading mills with specifications below 160. Because the batching cycle is slower than that of the three-dimensional auxiliary machine, the mixing cycle is generally required to be around 6 minutes. The effect is better when using granulated raw materials. Hygroscopic and astringent special materials need to be confirmed before use.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn