- Product Description

-

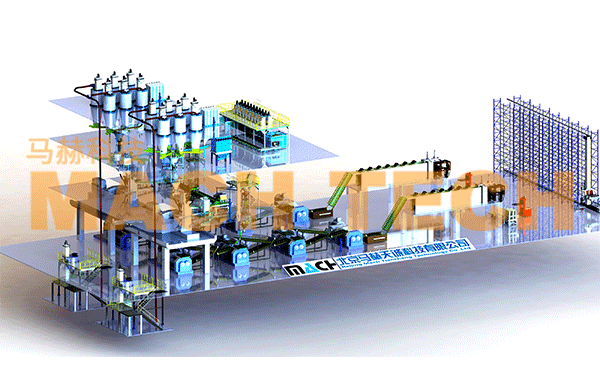

Large warehouse automatic storage & material (carbon black, white powder, fly ash, rubber powder, granular material) pneumatic conveying system

The positive pressure dense phase low-speed high-concentration (double-pipe, single-pipe) pneumatic conveying system is a product with internationally advanced technological level independently developed by our company based on the introduction of advanced German pneumatic conveying technology and combined with many years of practical experience.

This system is mainly applicable to the conveying of powdery and granular materials such as carbon black (granulation), clay, zinc oxide, limestone powder, slag, fly ash, cement raw materials, mineral powder, rubber powder, and grains. It mainly consists of a gas source and purification system, a material collection and unpacking and feeding system, a pressurization (bin, pump, tank) system, a conveying pipeline and distribution system, a large warehouse (ash silo) receiving system, a daily storage hopper secondary receiving system, a dust removal and pressure relief system, and a microcomputer and PLC control system. The control system's control methods include centralized control and on-site control, and the control form is a combination of automatic and manual control.

Compared with similar products and mechanical conveying, this system has the advantages of a good environment, high degree of automation, flexible layout, convenient installation, high mixing ratio, large conveying capacity, long conveying distance, low conveying breakage rate, no blockage (proprietary positive blowing and reverse suction anti-blocking technology), and safe and reliable operation, superior to other types of conveying methods.

Pneumatic conveying system

Category

- Product Description

-

Large warehouse automatic storage & material (carbon black, white powder, fly ash, rubber powder, granular material) pneumatic conveying system

The positive pressure dense phase low-speed high-concentration (double-pipe, single-pipe) pneumatic conveying system is a product with internationally advanced technological level independently developed by our company based on the introduction of advanced German pneumatic conveying technology and combined with many years of practical experience.

This system is mainly applicable to the conveying of powdery and granular materials such as carbon black (granulation), clay, zinc oxide, limestone powder, slag, fly ash, cement raw materials, mineral powder, rubber powder, and grains. It mainly consists of a gas source and purification system, a material collection and unpacking and feeding system, a pressurization (bin, pump, tank) system, a conveying pipeline and distribution system, a large warehouse (ash silo) receiving system, a daily storage hopper secondary receiving system, a dust removal and pressure relief system, and a microcomputer and PLC control system. The control system's control methods include centralized control and on-site control, and the control form is a combination of automatic and manual control.

Compared with similar products and mechanical conveying, this system has the advantages of a good environment, high degree of automation, flexible layout, convenient installation, high mixing ratio, large conveying capacity, long conveying distance, low conveying breakage rate, no blockage (proprietary positive blowing and reverse suction anti-blocking technology), and safe and reliable operation, superior to other types of conveying methods.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn