- Product Description

-

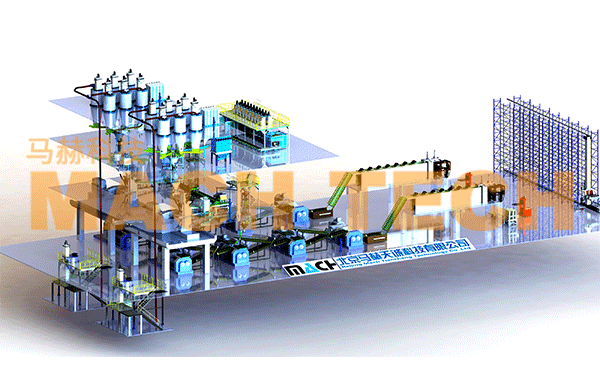

The automatic batching system for silica gel/insulators has the following advanced features compared to previous processes and equipment:

1. This system meets the requirements of dozens of kneading machines for the storage, batching, weighing, and feeding of precipitated/gas-phase white carbon black;

2. It realizes linkage control with the kneading machine, achieves integrated line information management, and improves the level of intelligent management;

3. It adopts modular group design, which is more convenient for equipment maintenance and repair. The sub-station control and metering weighing operate independently, ensuring a lower failure rate;

4. Intermittent feeding of the reduced-capacity hopper meets the large-capacity (500KG) batching requirements of the silica gel meshing production process, avoiding large-capacity material preparation hoppers.

5. It realizes continuous feeding, the feeding speed can be adjusted, and the metering is stable;

6. Continuous cumulative metering, one-time adjustment of the error value, realizes the metering requirements of large capacity and high precision;

7. Customized solutions. Based on customer needs and actual conditions, we provide the most suitable technical solutions and full-process personalized services to meet customers' future development needs.

Automatic batching system for silicone rubber/insulators (automatic batching system for kneading machines)

- Product Description

-

The automatic batching system for silica gel/insulators has the following advanced features compared to previous processes and equipment:

1. This system meets the requirements of dozens of kneading machines for the storage, batching, weighing, and feeding of precipitated/gas-phase white carbon black;

2. It realizes linkage control with the kneading machine, achieves integrated line information management, and improves the level of intelligent management;

3. It adopts modular group design, which is more convenient for equipment maintenance and repair. The sub-station control and metering weighing operate independently, ensuring a lower failure rate;

4. Intermittent feeding of the reduced-capacity hopper meets the large-capacity (500KG) batching requirements of the silica gel meshing production process, avoiding large-capacity material preparation hoppers.

5. It realizes continuous feeding, the feeding speed can be adjusted, and the metering is stable;

6. Continuous cumulative metering, one-time adjustment of the error value, realizes the metering requirements of large capacity and high precision;

7. Customized solutions. Based on customer needs and actual conditions, we provide the most suitable technical solutions and full-process personalized services to meet customers' future development needs.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn