- Product Description

-

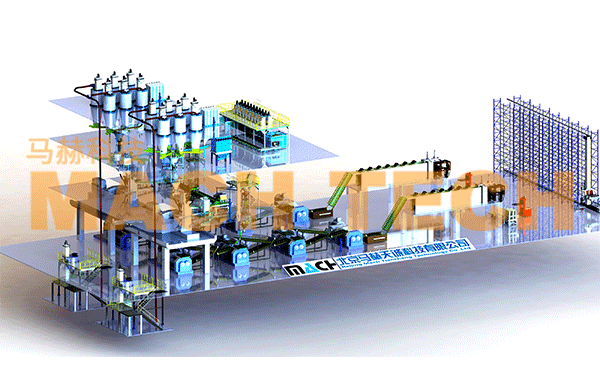

Shoe Material General Small Parts Batching Equipment

This equipment is only suitable for automatic batching of small materials for EVA granulation, EVA foaming, and TPR granulation products of shoe materials, and is not suitable for automatic batching of small materials for other products.

Features:

Realize the intelligent and automated production process of shoe material small parts batching, effectively preventing errors. The batching qualification rate reaches more than 98%, ensuring the reliability, uniformity, and stability of product quality. Dual-scale synchronous metering, high production efficiency.

High metering accuracy, the single material metering error can reach ±1g. Advanced control system, intuitive and easy-to-understand human-machine interface: with functions such as hierarchical management, formula input, real-time dynamic monitoring, automatic data recording, report statistics, and alarm prompts; conducive to quality traceability.

Significantly reduces the labor intensity of workers, and workers only need to complete bagging and bag removal. Compact structure and small footprint.

Robust and durable, good material, high configuration of components: all parts in contact with materials are made of 304 stainless steel, using Nissei Electric (Japan), Mettler Toledo electronic scales, Schneider low-voltage electrical appliances, and Omron photoelectric sensors. Under normal operation and maintenance, the service life is more than 10 years, with a 1-year warranty.

Quick installation and commissioning, no on-site installation and commissioning required for customers, ready to use after power-on. Simple operation, one-button start. Convenient maintenance, easy disassembly and cleaning, and equipped with an electronic scale calibration device.

Effectively improves the working environment and has low energy consumption. The comprehensive investment recovery period is up to 1 year.

General shoe material accessories system

- Product Description

-

Shoe Material General Small Parts Batching Equipment

This equipment is only suitable for automatic batching of small materials for EVA granulation, EVA foaming, and TPR granulation products of shoe materials, and is not suitable for automatic batching of small materials for other products.

Features:

Realize the intelligent and automated production process of shoe material small parts batching, effectively preventing errors. The batching qualification rate reaches more than 98%, ensuring the reliability, uniformity, and stability of product quality. Dual-scale synchronous metering, high production efficiency.

High metering accuracy, the single material metering error can reach ±1g. Advanced control system, intuitive and easy-to-understand human-machine interface: with functions such as hierarchical management, formula input, real-time dynamic monitoring, automatic data recording, report statistics, and alarm prompts; conducive to quality traceability.

Significantly reduces the labor intensity of workers, and workers only need to complete bagging and bag removal. Compact structure and small footprint.

Robust and durable, good material, high configuration of components: all parts in contact with materials are made of 304 stainless steel, using Nissei Electric (Japan), Mettler Toledo electronic scales, Schneider low-voltage electrical appliances, and Omron photoelectric sensors. Under normal operation and maintenance, the service life is more than 10 years, with a 1-year warranty.

Quick installation and commissioning, no on-site installation and commissioning required for customers, ready to use after power-on. Simple operation, one-button start. Convenient maintenance, easy disassembly and cleaning, and equipped with an electronic scale calibration device.

Effectively improves the working environment and has low energy consumption. The comprehensive investment recovery period is up to 1 year.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn