- Product Description

-

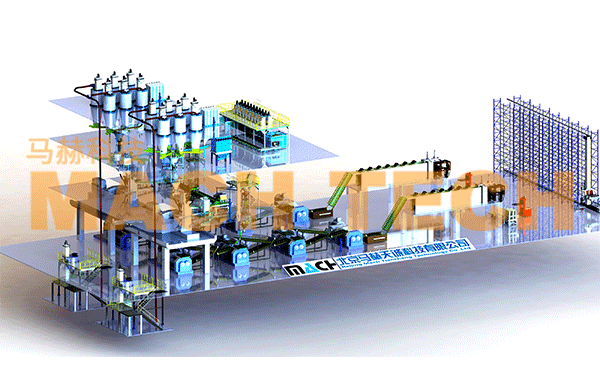

Features of the Series Once-Through Rubber Refining System

1. The series-type internal mixer completes the final and master mixing processes in one pass, increasing production capacity by approximately 100%;

2. Both master mixing and final mixing use the same PLC for online control of rubber mixing quality fluctuations;

The compounded rubber uses a one-pass mixing method, which can improve the mechanical shearing efficiency of the rubber, making the carbon black and various compounding agents more evenly dispersed, improving the tensile strength, wear resistance, and fatigue resistance of the rubber, reducing the Mooney viscosity, and other physical properties, improving the quality of the compounded rubber and products;

3. Filling powder and small auxiliary agents are all enclosed transportation and enclosed mixing, with less pollution;

4. The rotor dustproof seal wear ring uses C-C composite material, requiring only a small amount of oil. This reduces oil contamination of the rubber and saves approximately 40% or more oil compared to traditional methods;

5. Using a series internal mixer greatly shortens the auxiliary time;

6. Reduces the number of open mixers and other auxiliary equipment used;

7. Using a series internal mixer reduces the floor space of the rubber mixing workshop, saving on construction investment;

8. Using a fully automatic open mixer greatly reduces the labor intensity of workers;

9. Because of the vulcanization in the lower internal mixer, the open mixer refines rubber at below 90 degrees, and the rubber cooler does not produce any smoke.

Series one-time rubber refining system

- Product Description

-

Features of the Series Once-Through Rubber Refining System

1. The series-type internal mixer completes the final and master mixing processes in one pass, increasing production capacity by approximately 100%;

2. Both master mixing and final mixing use the same PLC for online control of rubber mixing quality fluctuations;

The compounded rubber uses a one-pass mixing method, which can improve the mechanical shearing efficiency of the rubber, making the carbon black and various compounding agents more evenly dispersed, improving the tensile strength, wear resistance, and fatigue resistance of the rubber, reducing the Mooney viscosity, and other physical properties, improving the quality of the compounded rubber and products;

3. Filling powder and small auxiliary agents are all enclosed transportation and enclosed mixing, with less pollution;

4. The rotor dustproof seal wear ring uses C-C composite material, requiring only a small amount of oil. This reduces oil contamination of the rubber and saves approximately 40% or more oil compared to traditional methods;

5. Using a series internal mixer greatly shortens the auxiliary time;

6. Reduces the number of open mixers and other auxiliary equipment used;

7. Using a series internal mixer reduces the floor space of the rubber mixing workshop, saving on construction investment;

8. Using a fully automatic open mixer greatly reduces the labor intensity of workers;

9. Because of the vulcanization in the lower internal mixer, the open mixer refines rubber at below 90 degrees, and the rubber cooler does not produce any smoke.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn