- Product Description

-

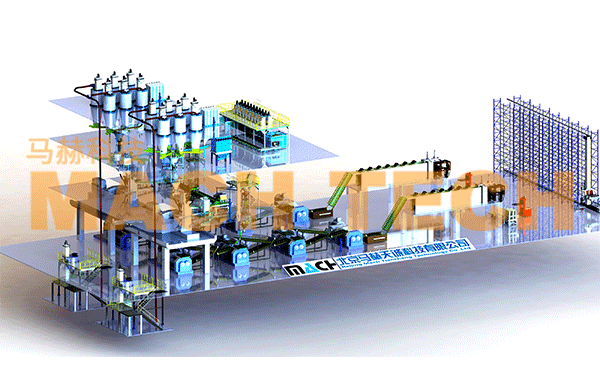

Low-temperature one-step rubber compounding system

1. The compounding rubber uses a one-step mixing method, which can improve the mechanical shearing efficiency of the rubber, making the carbon black and various compounding agents more evenly dispersed. This effectively avoids the formation of carbon black gel during the rubber mixing process, reduces the occurrence of irreversible chemical cracking of rubber molecular chains, increases the number of reversible mechanically sheared molecular chains, improves the tensile strength, wear resistance, and fatigue resistance of the rubber, reduces the Mooney viscosity, and other physical properties, improving the quality of the compounded rubber and products.

2. Using an open mill vulcanization system, the open mills are arranged in series and parallel to improve the sulfur dispersion effect;

3. Reduce the energy consumption of the traditional process using high-energy-consuming internal mixers for multi-stage mixing; save about 25% of electricity;

4. It also maximizes the production capacity of the internal mixer. The average number of sections of the compounded rubber is 1.6 sections, which means the production capacity is increased by 1.6 times;

5. Improve the automation level of the finishing line;

6. The quality of the rubber is uniform and stable;

7. Save manpower and management costs.

Low-temperature one-step rubber refining system

- Product Description

-

Low-temperature one-step rubber compounding system

1. The compounding rubber uses a one-step mixing method, which can improve the mechanical shearing efficiency of the rubber, making the carbon black and various compounding agents more evenly dispersed. This effectively avoids the formation of carbon black gel during the rubber mixing process, reduces the occurrence of irreversible chemical cracking of rubber molecular chains, increases the number of reversible mechanically sheared molecular chains, improves the tensile strength, wear resistance, and fatigue resistance of the rubber, reduces the Mooney viscosity, and other physical properties, improving the quality of the compounded rubber and products.

2. Using an open mill vulcanization system, the open mills are arranged in series and parallel to improve the sulfur dispersion effect;

3. Reduce the energy consumption of the traditional process using high-energy-consuming internal mixers for multi-stage mixing; save about 25% of electricity;

4. It also maximizes the production capacity of the internal mixer. The average number of sections of the compounded rubber is 1.6 sections, which means the production capacity is increased by 1.6 times;

5. Improve the automation level of the finishing line;

6. The quality of the rubber is uniform and stable;

7. Save manpower and management costs.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn