- Product Description

-

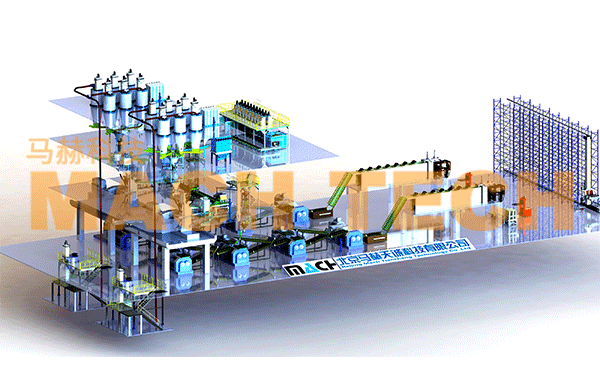

Automated Production Line and Full Process Control System for Friction Materials

This system mainly realizes the automated production and full process control of various brake pads and clutch pads for trains and automobiles. It provides a complete automated production line addressing the requirements of raw material storage, automatic weighing, batching, conveying, mixing, coarse crushing, fine crushing, constant temperature storage, pressing and molding, grinding, testing, finished product storage, and environmental protection. The system adopts a three-dimensional or planar structural design. The intelligent automatic batching system plays an important role in improving management level, product quality, and product stability. Through years of continuous technological innovation and improvement by our company, this system has been well received by customers.

Compared with traditional production equipment in the friction material industry, it has the following characteristics:

1. Improves information management level. Using a full process control system, combining the latest information technology with production management and production processes, it can achieve: Raw material management, Production schedule management, Production recipe management, Mixing optimization function, Data report management, Dynamic real time monitoring, Quality tracing function, System alarm prompting function, Fault diagnosis analysis, Remote monitoring function.

2. Improves and optimizes the production process. Through integral calculation and logical control of parameters such as mixing time, power, and speed of the sand mixer, optimized mixing is achieved.

3. Fully automated production eliminates human factors, improving the reliability, uniformity, and stability of product quality, and increasing the product qualification rate.

4. Improves the working environment. Unpacking can be done in the warehouse, reducing material handling steps. Raw material unpacking is separated from the production area, keeping the environment clean. The entire material handling process is equipped with a dust collection and recycling system to ensure no dust flying or leakage, and no waste.

5. Improves production efficiency. High measurement accuracy is achieved using the latest developed synchronous measurement method and track cycle feeding method. It reduces labor intensity, lowers production costs, and only requires 1-2 people for the entire line.

6. Low factory investment and flexible solutions. Steel structure factory building, only 11 meters net height is required.

7. Simple operation, convenient maintenance, stable operation. Open Chinese and English human-machine interface, automatic detection of operating conditions, alarm location and solution suggestions are given when abnormalities occur. Key components are all imported or joint venture brands, stable and reliable. Remote monitoring and after-sales support are available.

8. Creates greater value for users, enhancing users' core competitiveness and market advantages.

Automated production line and information management system for friction materials

- Product Description

-

Automated Production Line and Full Process Control System for Friction Materials

This system mainly realizes the automated production and full process control of various brake pads and clutch pads for trains and automobiles. It provides a complete automated production line addressing the requirements of raw material storage, automatic weighing, batching, conveying, mixing, coarse crushing, fine crushing, constant temperature storage, pressing and molding, grinding, testing, finished product storage, and environmental protection. The system adopts a three-dimensional or planar structural design. The intelligent automatic batching system plays an important role in improving management level, product quality, and product stability. Through years of continuous technological innovation and improvement by our company, this system has been well received by customers.

Compared with traditional production equipment in the friction material industry, it has the following characteristics:

1. Improves information management level. Using a full process control system, combining the latest information technology with production management and production processes, it can achieve: Raw material management, Production schedule management, Production recipe management, Mixing optimization function, Data report management, Dynamic real time monitoring, Quality tracing function, System alarm prompting function, Fault diagnosis analysis, Remote monitoring function.

2. Improves and optimizes the production process. Through integral calculation and logical control of parameters such as mixing time, power, and speed of the sand mixer, optimized mixing is achieved.

3. Fully automated production eliminates human factors, improving the reliability, uniformity, and stability of product quality, and increasing the product qualification rate.

4. Improves the working environment. Unpacking can be done in the warehouse, reducing material handling steps. Raw material unpacking is separated from the production area, keeping the environment clean. The entire material handling process is equipped with a dust collection and recycling system to ensure no dust flying or leakage, and no waste.

5. Improves production efficiency. High measurement accuracy is achieved using the latest developed synchronous measurement method and track cycle feeding method. It reduces labor intensity, lowers production costs, and only requires 1-2 people for the entire line.

6. Low factory investment and flexible solutions. Steel structure factory building, only 11 meters net height is required.

7. Simple operation, convenient maintenance, stable operation. Open Chinese and English human-machine interface, automatic detection of operating conditions, alarm location and solution suggestions are given when abnormalities occur. Key components are all imported or joint venture brands, stable and reliable. Remote monitoring and after-sales support are available.

8. Creates greater value for users, enhancing users' core competitiveness and market advantages.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn