- Product Description

-

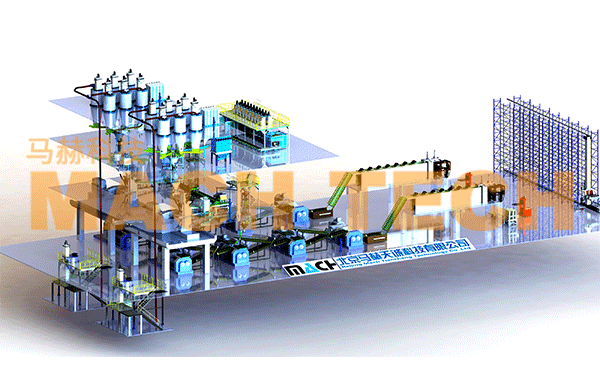

Automatic Packaging and Palletizing Production Line for Big Bags and Small Bags

This production line can automatically package and palletize both big bags and 25kg small bags.

The automatic big bag packaging machine is a multi-purpose automatic quantitative packaging machine integrating electronic weighing, automatic unhooking, and dust removal.

It includes a feeder, automatic bag hanging mechanism, bag inflation device, bag clamping mechanism, metering conveying unit, and control system. Workers manually hang the packaging bag on the hook, put the inlet into the outlet, and the clamping device automatically clamps the inlet for weighing and filling. After filling, the big bag is automatically lowered to the conveyor, the hook automatically disengages, and the package is conveyed to the operator's workstation for manual sealing, completing the quantitative packaging of the big bag.

The small bag automatic packaging and palletizing production line is a fully automatic packaging and conveying line integrating automatic bagging, automatic opening, automatic filling, automatic sealing, finished product conveying, bag shaping, and automatic palletizing. It includes a weighing scale, bag storage, automatic bagging and bagging mechanism, automatic filling device, strapping conveying mechanism, automatic sealing machine, bag inverting unit, shaping unit, palletizing workstation, palletizing robot, pallet storage, pallet conveying unit, palletizing robot, and control system. The entire production line operates fully automatically, only requiring manual replenishment of empty bags and pallets, and transfer of full pallets. The control system can establish an easy-to-operate control platform for integrated control of system operation. The system can also be equipped with a weight detection unit, a metal detection unit, and a waste discharge workstation to control the final product quality.

Automatic paper bag packaging and palletizing production line

- Product Description

-

Automatic Packaging and Palletizing Production Line for Big Bags and Small Bags

This production line can automatically package and palletize both big bags and 25kg small bags.

The automatic big bag packaging machine is a multi-purpose automatic quantitative packaging machine integrating electronic weighing, automatic unhooking, and dust removal.

It includes a feeder, automatic bag hanging mechanism, bag inflation device, bag clamping mechanism, metering conveying unit, and control system. Workers manually hang the packaging bag on the hook, put the inlet into the outlet, and the clamping device automatically clamps the inlet for weighing and filling. After filling, the big bag is automatically lowered to the conveyor, the hook automatically disengages, and the package is conveyed to the operator's workstation for manual sealing, completing the quantitative packaging of the big bag.

The small bag automatic packaging and palletizing production line is a fully automatic packaging and conveying line integrating automatic bagging, automatic opening, automatic filling, automatic sealing, finished product conveying, bag shaping, and automatic palletizing. It includes a weighing scale, bag storage, automatic bagging and bagging mechanism, automatic filling device, strapping conveying mechanism, automatic sealing machine, bag inverting unit, shaping unit, palletizing workstation, palletizing robot, pallet storage, pallet conveying unit, palletizing robot, and control system. The entire production line operates fully automatically, only requiring manual replenishment of empty bags and pallets, and transfer of full pallets. The control system can establish an easy-to-operate control platform for integrated control of system operation. The system can also be equipped with a weight detection unit, a metal detection unit, and a waste discharge workstation to control the final product quality.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn