- Product Description

-

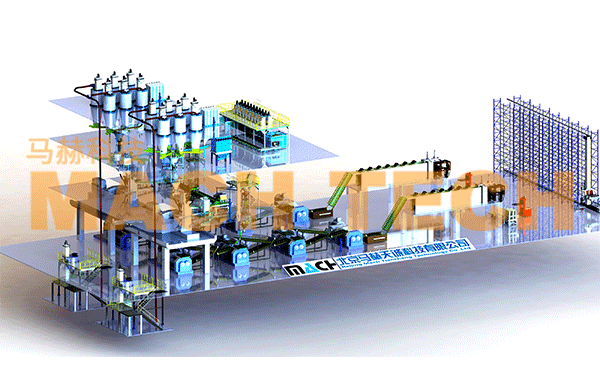

This system mainly realizes the automated production and full process control of masterbatch products. It addresses the requirements for storage, automatic weighing, batching, transportation, and kneading and mixing of large materials (carriers), medium materials (resins, etc.), small materials (additives), and pigments. Interlocked control with the kneader/mixer host, providing a complete set of automatic weighing and mixing. The intelligent automatic mixing system plays an important role in improving the production environment, improving management level, improving product quality, and maintaining product stability.

Compared with traditional masterbatch production equipment, it has the following features:

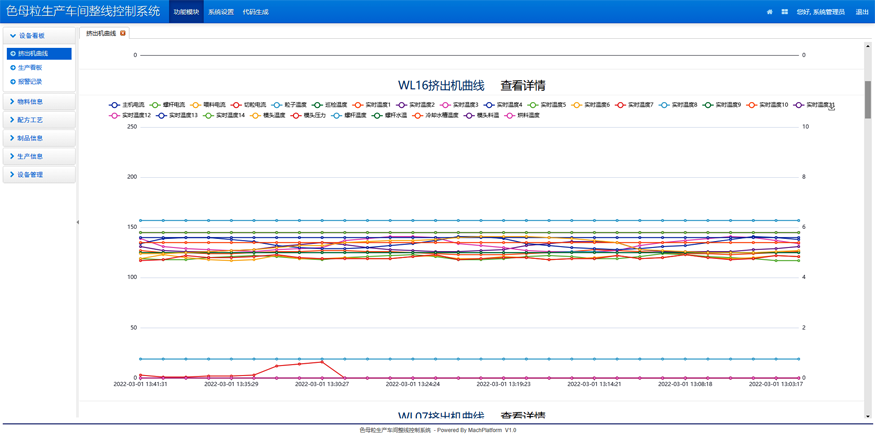

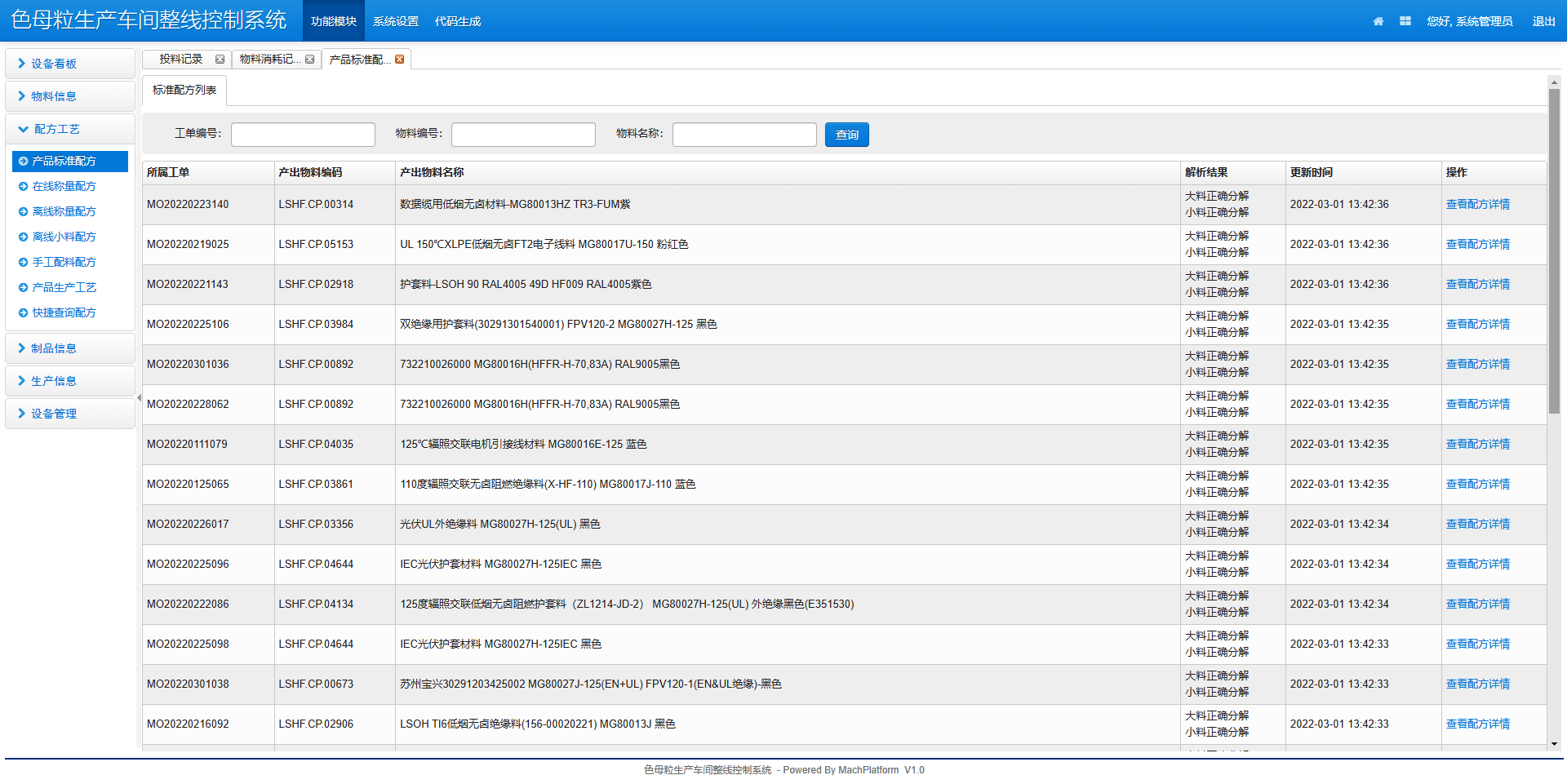

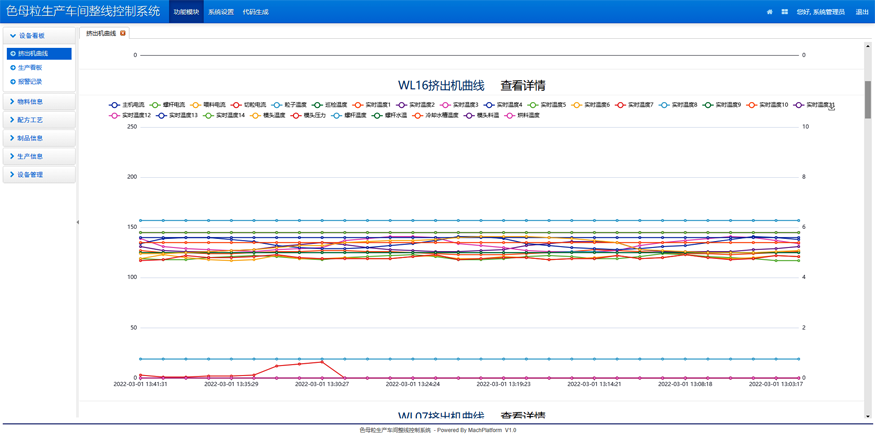

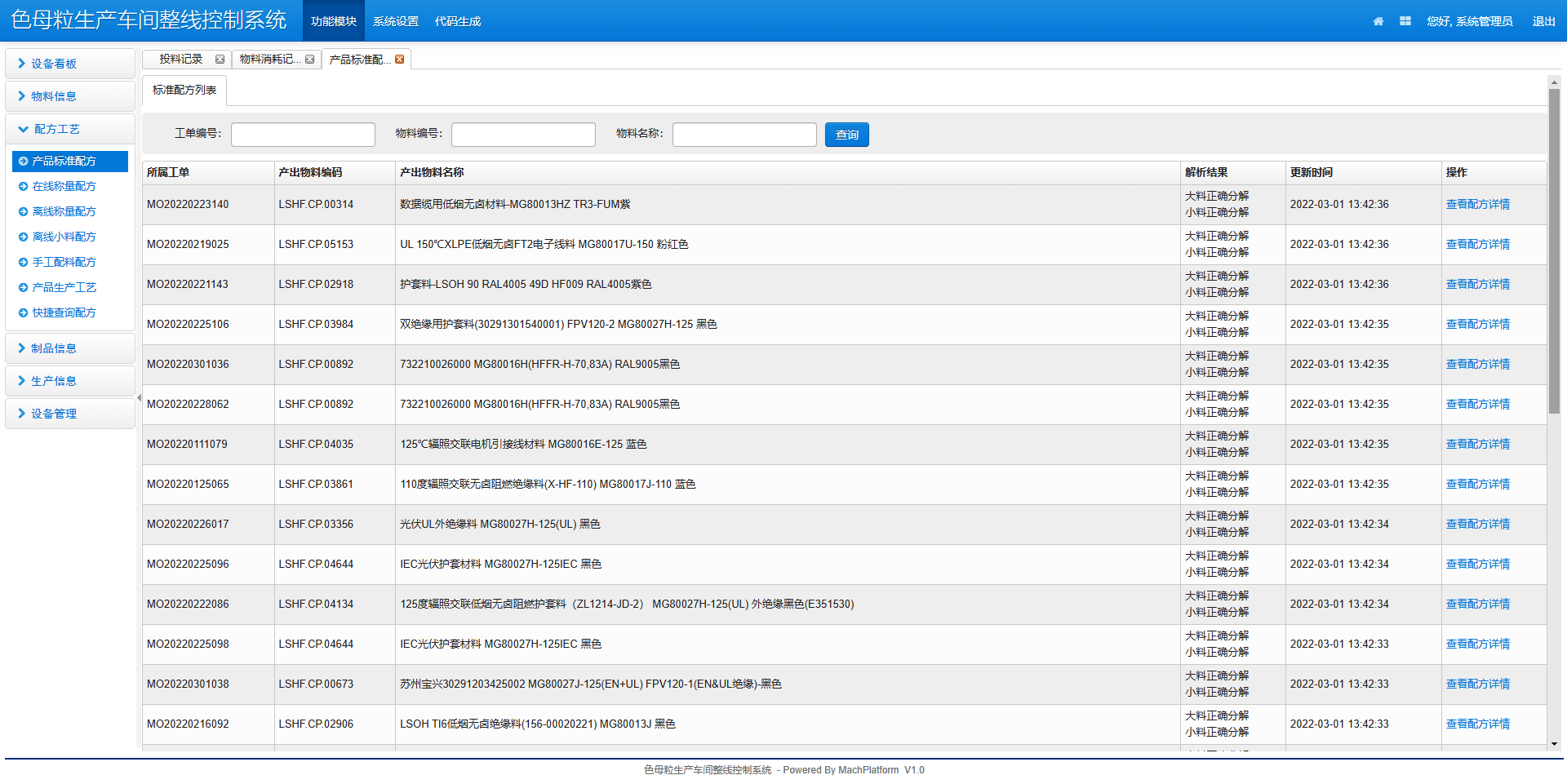

1 Improve the level of information management, adopt a full-process control system, combining the latest information technology with production management and production processes, can achieve: production raw material management Raw material management Production schedule management Production schedule management Production recipe management Production recipe management Mixing optimization function Mixing optimization function Data report management Data report management Dynamic real time monitoring Dynamic real time monitoring Quality tracing function Quality tracing function System alarm prompting function System alarm prompting function Fault diagnosis analysis Fault diagnosis analysis Remote monitoring function Remote monitoring function 。

2 Improve and optimize the production process. Through the integral calculation and logical control of parameters such as the mixing time, power, and speed of the kneader and mixer, optimized mixing is achieved.

3 More accurate measurement, thereby improving the reliability, uniformity, and stability of masterbatch quality and increasing the product pass rate.

4 Production environment is cleaner, and labor costs are lower.

5、 Higher production efficiency and significantly increased production capacity;

6、 Easy operation, convenient maintenance, stable operation, and remote monitoring capability.

7 Create greater value for users, enabling users to enhance their core competitiveness and market advantages.

Masterbatch carrier/pigment automatic batching and mixing system

Category

- Product Description

-

This system mainly realizes the automated production and full process control of masterbatch products. It addresses the requirements for storage, automatic weighing, batching, transportation, and kneading and mixing of large materials (carriers), medium materials (resins, etc.), small materials (additives), and pigments. Interlocked control with the kneader/mixer host, providing a complete set of automatic weighing and mixing. The intelligent automatic mixing system plays an important role in improving the production environment, improving management level, improving product quality, and maintaining product stability.

Compared with traditional masterbatch production equipment, it has the following features:

1 Improve the level of information management, adopt a full-process control system, combining the latest information technology with production management and production processes, can achieve: production raw material management Raw material management Production schedule management Production schedule management Production recipe management Production recipe management Mixing optimization function Mixing optimization function Data report management Data report management Dynamic real time monitoring Dynamic real time monitoring Quality tracing function Quality tracing function System alarm prompting function System alarm prompting function Fault diagnosis analysis Fault diagnosis analysis Remote monitoring function Remote monitoring function 。

2 Improve and optimize the production process. Through the integral calculation and logical control of parameters such as the mixing time, power, and speed of the kneader and mixer, optimized mixing is achieved.

3 More accurate measurement, thereby improving the reliability, uniformity, and stability of masterbatch quality and increasing the product pass rate.

4 Production environment is cleaner, and labor costs are lower.

5、 Higher production efficiency and significantly increased production capacity;

6、 Easy operation, convenient maintenance, stable operation, and remote monitoring capability.

7 Create greater value for users, enabling users to enhance their core competitiveness and market advantages.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn