- Product Description

-

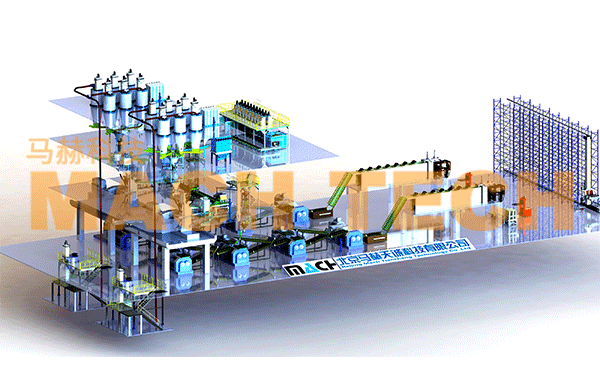

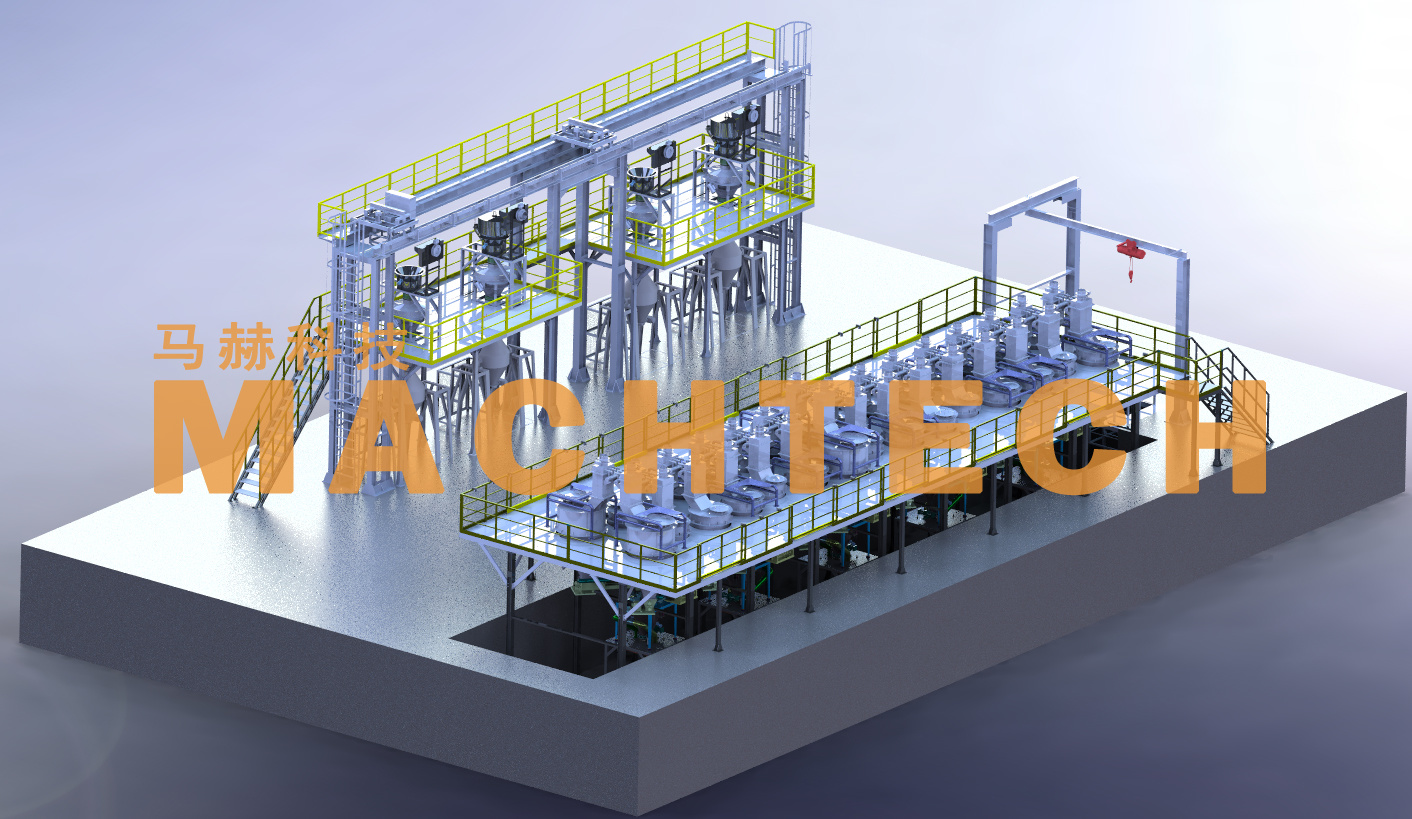

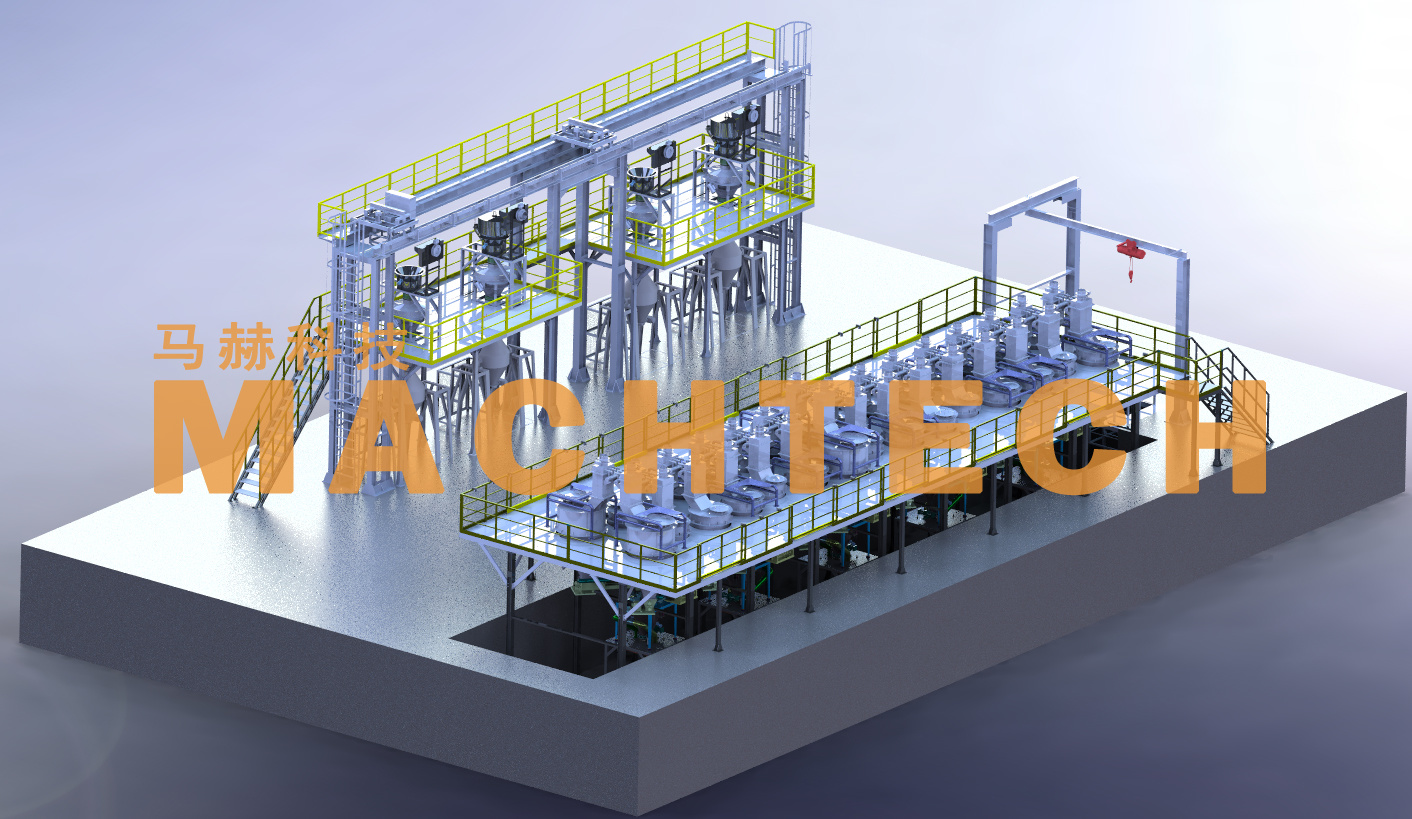

A new generation of welding materials handling overall solution, including: automatic welding materials batching system + Automatic welding materials Screening and mixing system System + Welding materials production MES System System + Intelligent three-dimensional warehouse for welding materials

Based on the stable and reliable equipment, the “Accurate, efficient and suitable ”as design concept, through intelligent upgrading, solves the problem of equipment production varying from person to person, helping customers improve overall production efficiency 30%, continuously promoting Welding materials industry automation, intelligence, and information upgrading.

Based on the thinking about the current situation of the welding materials industry and the insight into the development trend of the welding materials workshop, Maher Technology has established a professional R&D team for welding materials manufacturing equipment and a mature R&D and service system. It is the only domestic supplier that can provide integrated manufacturing equipment and system integration of automatic batching and screening of welding materials and management software. This system has been put into production and application in well-known domestic welding materials enterprises.

Compared with the traditional welding materials raw material processing methods, this system has four outstanding advantages:

First, the new generation of solutions is more mature

After Years of continuous research and development Innovation , Maher Technology Full series Conveying, metering and batching Equipment, whether in terms of performance or stability are continuously improving, which can further reduce manual labor and improve production efficiency. Realize all-round data control, provide customers with comprehensive production information, simplify workshop management, and realize a transparent and digital welding materials production workshop.

Second, higher degree of intelligence, workers Easier operation

Based on Maher Technology's self-developed Software platform, with “ As unmanned as possible ”as the goal, the software management of welding materials products on the same platform has been realized. By creating intelligent operation and maintenance, intelligent production, and intelligent service scenarios to reconstruct the relationship between people and equipment, making the equipment more intelligent, and the operation of people becomes simple and labor-saving, improving customer experience, and solving the problem of equipment use varying from person to person.

Third, the stability and reliability of the equipment have made a qualitative leap

Based on Maher Technology's innovative R&D platform, design experience Carry out Digital, platform Management , Through equipment reliability system engineering, reliability design, data analysis and testing of components are carried out to improve operational reliability and stability. In terms of delivery, based on the integrated design of machinery, electricity, gas, and software, standardized and modular components are realized. In the processing and assembly process, process control is carried out through standard specifications and special tooling to ensure a 100% pass rate upon delivery. 100%.

Fourth, strong overall solution delivery Delivery capability

Using modular and standardized methods to integrate Maher Technology More than 20 years of material handling experience And 3000 Multiple Sets of equipment operation experience are precipitated into a digital technology platform, customer needs are centered, and Continuous product life cycle R&D iteration is carried out to ensure the quality of product delivery. Through a perfect project management system, refined management has been achieved in project planning, risk, quality, and changes. Relying on Maher Technology's customer service cloud platform, it provides customers with 7*24 hours High-quality remote and localized services.

Next-generation welding material handling overall solution

- Product Description

-

A new generation of welding materials handling overall solution, including: automatic welding materials batching system + Automatic welding materials Screening and mixing system System + Welding materials production MES System System + Intelligent three-dimensional warehouse for welding materials

Based on the stable and reliable equipment, the “Accurate, efficient and suitable ”as design concept, through intelligent upgrading, solves the problem of equipment production varying from person to person, helping customers improve overall production efficiency 30%, continuously promoting Welding materials industry automation, intelligence, and information upgrading.

Based on the thinking about the current situation of the welding materials industry and the insight into the development trend of the welding materials workshop, Maher Technology has established a professional R&D team for welding materials manufacturing equipment and a mature R&D and service system. It is the only domestic supplier that can provide integrated manufacturing equipment and system integration of automatic batching and screening of welding materials and management software. This system has been put into production and application in well-known domestic welding materials enterprises.

Compared with the traditional welding materials raw material processing methods, this system has four outstanding advantages:

First, the new generation of solutions is more mature

After Years of continuous research and development Innovation , Maher Technology Full series Conveying, metering and batching Equipment, whether in terms of performance or stability are continuously improving, which can further reduce manual labor and improve production efficiency. Realize all-round data control, provide customers with comprehensive production information, simplify workshop management, and realize a transparent and digital welding materials production workshop.

Second, higher degree of intelligence, workers Easier operation

Based on Maher Technology's self-developed Software platform, with “ As unmanned as possible ”as the goal, the software management of welding materials products on the same platform has been realized. By creating intelligent operation and maintenance, intelligent production, and intelligent service scenarios to reconstruct the relationship between people and equipment, making the equipment more intelligent, and the operation of people becomes simple and labor-saving, improving customer experience, and solving the problem of equipment use varying from person to person.

Third, the stability and reliability of the equipment have made a qualitative leap

Based on Maher Technology's innovative R&D platform, design experience Carry out Digital, platform Management , Through equipment reliability system engineering, reliability design, data analysis and testing of components are carried out to improve operational reliability and stability. In terms of delivery, based on the integrated design of machinery, electricity, gas, and software, standardized and modular components are realized. In the processing and assembly process, process control is carried out through standard specifications and special tooling to ensure a 100% pass rate upon delivery. 100%.

Fourth, strong overall solution delivery Delivery capability

Using modular and standardized methods to integrate Maher Technology More than 20 years of material handling experience And 3000 Multiple Sets of equipment operation experience are precipitated into a digital technology platform, customer needs are centered, and Continuous product life cycle R&D iteration is carried out to ensure the quality of product delivery. Through a perfect project management system, refined management has been achieved in project planning, risk, quality, and changes. Relying on Maher Technology's customer service cloud platform, it provides customers with 7*24 hours High-quality remote and localized services.

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn