- Product Description

-

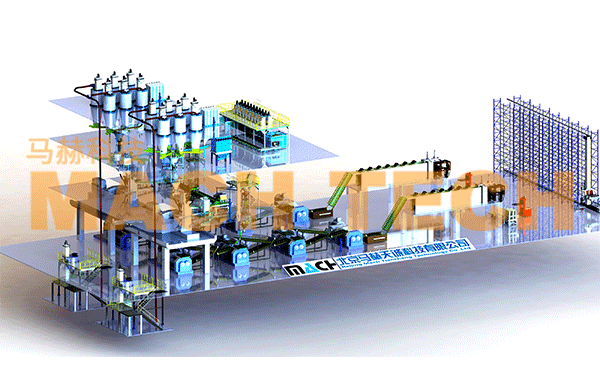

MACH-MES Intelligent Control System for Mahe Plastic Production Workshop

In the rubber and plastics manufacturing industry, precise control of the production process is the lifeline of product quality and production efficiency. Traditional models face severe challenges such as raw material backlog and shortages, human intervention errors, low cross-link collaboration efficiency, large quality fluctuations, opaque process parameters, and serious energy waste.

Faced with bottlenecks and pain points, how can we break through?

Mahe Technology - Intelligent Control System, taking MES as the core, deeply integrates IIoT and AGV logistics to create a digital, intelligent, and unmanned full-process solution.

Mahe Technology - Intelligent Control System for Mixing Workshop has complete MES functions and full-process control: including intelligent warehousing, work order scheduling, equipment status, real-time monitoring and warning of energy consumption, automatic generation and analysis of production reports, and quality traceability. It can seamlessly connect with ERP, PLM, and SWM, allowing production to enter the fast lane of intelligent manufacturing and information management.

Compared with traditional MES, we focus more on the collection of production process data and full-process digital monitoring. By integrating Industrial Internet of Things (IIoT) technology, we perform real-time data acquisition on key equipment and production links, including high-speed mixers, mixing machines, extruders, cooling granulation, etc., and deeply integrate process control for precise and controllable results, making every piece of data create value.

We have more professional full-link data traceability, from raw material warehousing scanning → parameter binding → real-time quality inspection → finished and semi-finished product output label printing. Users can quickly locate the production batch, equipment status, and exception handling through the finished product barcode. They can also quickly locate all affected finished products, inventory, and customer lists by querying the problematic batch.

It can be deeply integrated with the AGV scheduling system to optimize the transportation path of raw materials from the warehouse to the production line units, reduce manual intervention, save labor costs, and reduce loss rates. It supports a mixed warehousing mode of vertical and horizontal warehouses. Logistics coordination and inventory optimization effectively avoid raw material backlog or shortages, increasing product added value, optimizing cost results, expanding market share, and improving the company's overall competitiveness.

Mahe Technology's workshop intelligent control system adopts a modular and professional design for the plastics industry. It allows users to select suitable modules based on their needs, offering stronger adaptability and shorter implementation cycles. With over 20 years of accumulation and precipitation, Mahe has richer experience in process and equipment, production line data acquisition, and intelligent control. Our independently developed standardized control software is more mature, stable, and cost-effective. We work hand-in-hand with our customers to continuously innovate and promote the rapid transformation and upgrading of the plastics industry to "intelligent manufacturing".

Intelligent Control System Mach-MES

Category

Keywords

- Product Description

-

MACH-MES Intelligent Control System for Mahe Plastic Production Workshop

In the rubber and plastics manufacturing industry, precise control of the production process is the lifeline of product quality and production efficiency. Traditional models face severe challenges such as raw material backlog and shortages, human intervention errors, low cross-link collaboration efficiency, large quality fluctuations, opaque process parameters, and serious energy waste.

Faced with bottlenecks and pain points, how can we break through?

Mahe Technology - Intelligent Control System, taking MES as the core, deeply integrates IIoT and AGV logistics to create a digital, intelligent, and unmanned full-process solution.

Mahe Technology - Intelligent Control System for Mixing Workshop has complete MES functions and full-process control: including intelligent warehousing, work order scheduling, equipment status, real-time monitoring and warning of energy consumption, automatic generation and analysis of production reports, and quality traceability. It can seamlessly connect with ERP, PLM, and SWM, allowing production to enter the fast lane of intelligent manufacturing and information management.

Compared with traditional MES, we focus more on the collection of production process data and full-process digital monitoring. By integrating Industrial Internet of Things (IIoT) technology, we perform real-time data acquisition on key equipment and production links, including high-speed mixers, mixing machines, extruders, cooling granulation, etc., and deeply integrate process control for precise and controllable results, making every piece of data create value.

We have more professional full-link data traceability, from raw material warehousing scanning → parameter binding → real-time quality inspection → finished and semi-finished product output label printing. Users can quickly locate the production batch, equipment status, and exception handling through the finished product barcode. They can also quickly locate all affected finished products, inventory, and customer lists by querying the problematic batch.

It can be deeply integrated with the AGV scheduling system to optimize the transportation path of raw materials from the warehouse to the production line units, reduce manual intervention, save labor costs, and reduce loss rates. It supports a mixed warehousing mode of vertical and horizontal warehouses. Logistics coordination and inventory optimization effectively avoid raw material backlog or shortages, increasing product added value, optimizing cost results, expanding market share, and improving the company's overall competitiveness.

Mahe Technology's workshop intelligent control system adopts a modular and professional design for the plastics industry. It allows users to select suitable modules based on their needs, offering stronger adaptability and shorter implementation cycles. With over 20 years of accumulation and precipitation, Mahe has richer experience in process and equipment, production line data acquisition, and intelligent control. Our independently developed standardized control software is more mature, stable, and cost-effective. We work hand-in-hand with our customers to continuously innovate and promote the rapid transformation and upgrading of the plastics industry to "intelligent manufacturing".

Related Products

Product Inquiry

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn