What are the benefits of an automatic batching system for magnetic materials?

Published Time:

2022-06-24

Automatic batching of magnetic materials is a crucial aspect of production in various sectors, including chemicals, metallurgy, building materials, pharmaceuticals, grains, feed, and food. Raw material technology is a critical stage in the production process, significantly impacting output and quality. Traditional industrial raw material systems are not fully intelligent, informational, or automated, presenting numerous challenges. Let's explore the advantages of an automatic batching system for magnetic materials.

Automatic batching of magnetic materials is a crucial aspect of production in various sectors, including chemicals, metallurgy, building materials, pharmaceuticals, grains, feed, and food. Raw material technology is a vital link in the production process, significantly impacting output and quality. Traditional industrial raw material systems are not fully intelligent, informational, or automated, presenting numerous challenges. Let's explore the advantages of an automatic batching system for magnetic materials!

1. The speed and accuracy of raw materials cannot meet production demands;

2. It cannot meet the management needs of various materials;

3. It cannot meet the needs of formula conversion and adjustment;

4. Materials may be affected by ambient temperature and humidity;

5. High dust levels and poor environment at the production site;

6. Untimely information transmission, resulting in a disconnect between management and production.

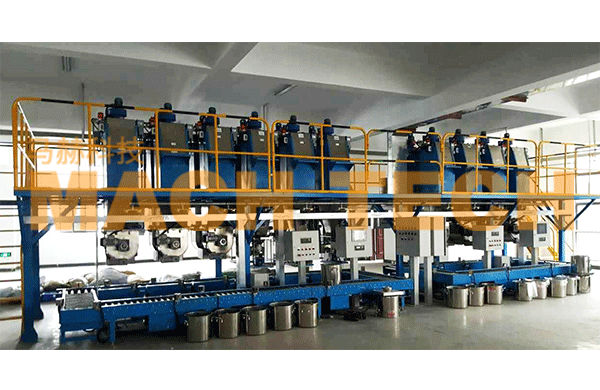

Given these numerous challenges, traditional industrial raw material methods can no longer meet the production needs of enterprises, impacting production efficiency and quality. Automated and intelligent raw material control systems have become a pressing issue for many manufacturing companies. Automatic batching of magnetic materials prioritizes customer material properties, formulations, and production techniques, utilizing belts or metering screws for transportation. It manages the proportioning of bulk materials and various data management during production according to user requirements. This system integrates hardware, software, basic production, and management into a unified system, helping companies improve production efficiency, optimize the production environment, reduce costs, and enhance scientific management.

In terms of metering control, the weighing sensors and speed sensors of the automatic batching system for magnetic materials boast high sensitivity. Core components utilize imported brands, minimizing environmental impact and ensuring higher metering accuracy. Precise metering accuracy guarantees accurate control and safeguards production quality. The system employs a high-performance programmable controller, while the host computer handles formula management, screen interaction, and weight data storage, query, and printing, achieving raw material automation. The weighing instrument is no longer a simple calculation and display device; it features self-diagnosis, automatic zeroing, tare setting, dynamic weighing, and data communication, enhancing accuracy while strengthening automated raw material control.

For complex and diverse formulations and multiple raw materials, the automatic batching system for magnetic materials can flexibly adjust the proportions of various materials based on the customer's actual formulation and production process. Customers only need to set parameters on the host computer. To address the issues of variable and harsh on-site environments, high dust levels, and potential material sensitivity to temperature and humidity, the batching control system can select appropriate conveying and metering equipment, such as screw feeders and belt conveyors, and incorporate sealing structures. This improves and optimizes the production environment, prevents material spillage and waste, and protects the materials.

The above describes the advantages of an automatic batching system for magnetic materials. For more information, please contact us!

Tags:

Recommended News

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn