Products

Hot Products

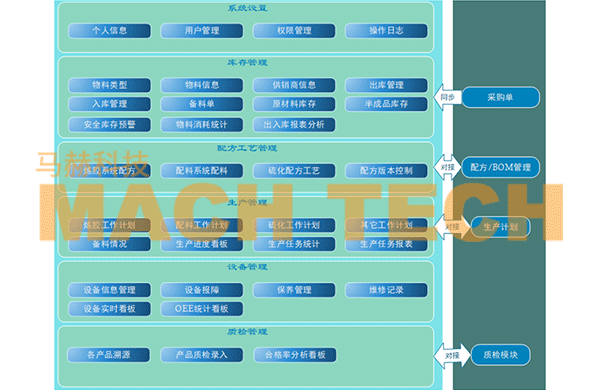

MES Manufacturing Execution System

MES is a production information management system. It optimizes the entire process from order placement to product completion through information transmission, responds to and reports on real-time events occurring in the factory workshop in a timely manner, and uses accurate data for guidance and processing. It realizes the digitalization, intelligence, and visualization of the production manufacturing process.

Intelligent Monitoring and Manufacturing System for Production Process Information

Achieve full traceability of product production through information technology, real-time data acquisition, and grasp of product production process and quality management. Integrate workshop production planning, scheduling, material flow tracking, process control and monitoring, quality management, equipment maintenance, and information management into one, ultimately achieving an optimized automated manufacturing platform strategy.

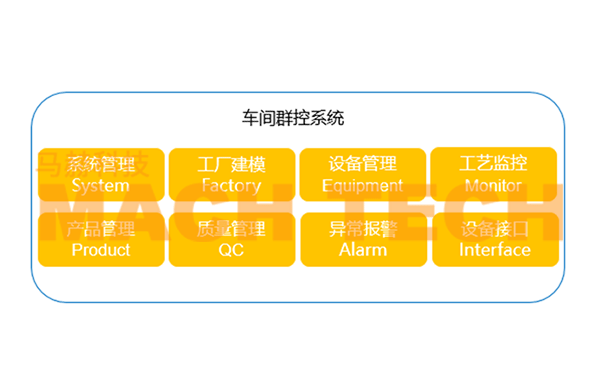

Centralized control and management of production line equipment, real-time collection of production operation parameters, production product quality analysis and monitoring, timely alarm and notification of relevant personnel in case of abnormalities, and improvement of the automation and informatization level of the production line.

Product traceability is achieved throughout the entire process using advanced barcode technology. Batch numbers, barcodes, and labels are set according to our own rules, enabling functions such as quick inventory checks to achieve FIFO (First-In, First-Out), error prevention, loss prevention, and fool-proofing.

RFID (Radio Frequency Identification) technology enables ultra-long-range identification and automatic sensing of target objects to acquire relevant data. Identification requires no human intervention and can operate in various harsh environments. It also provides personalized customization of tags, enabling full process information traceability.

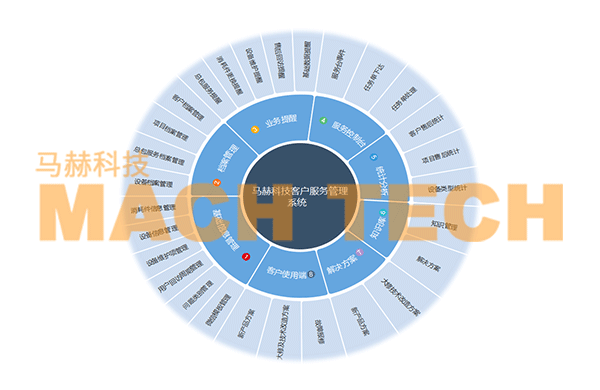

Customer Service Management Cloud Platform

Customer Service Management Cloud Platform Solution From the customer's perspective, we provide the most suitable technical solutions and comprehensive personalized services based on each customer's needs and actual situation. Our independently developed customer relationship management system can realize functions such as online customer return visits and tracking, customer file creation, equipment maintenance reminders, usage problem collection, repair real-time reminders, after-sales progress tracking, service process recording, data analysis and summary, and product improvement and optimization. Customers can directly log in to the system to report repairs via mobile APP, official account, or PC. The system will immediately remind our customer service personnel. After-sales engineers quickly complete after-sales service remotely or on-site, and customers can check the service status at any time during the process. This system is open to all users and is sold globally.

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn