Products

Hot Products

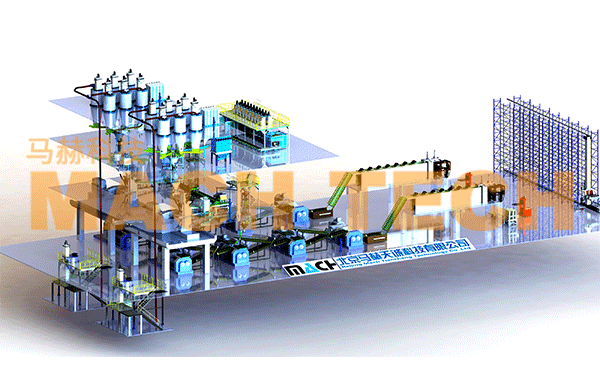

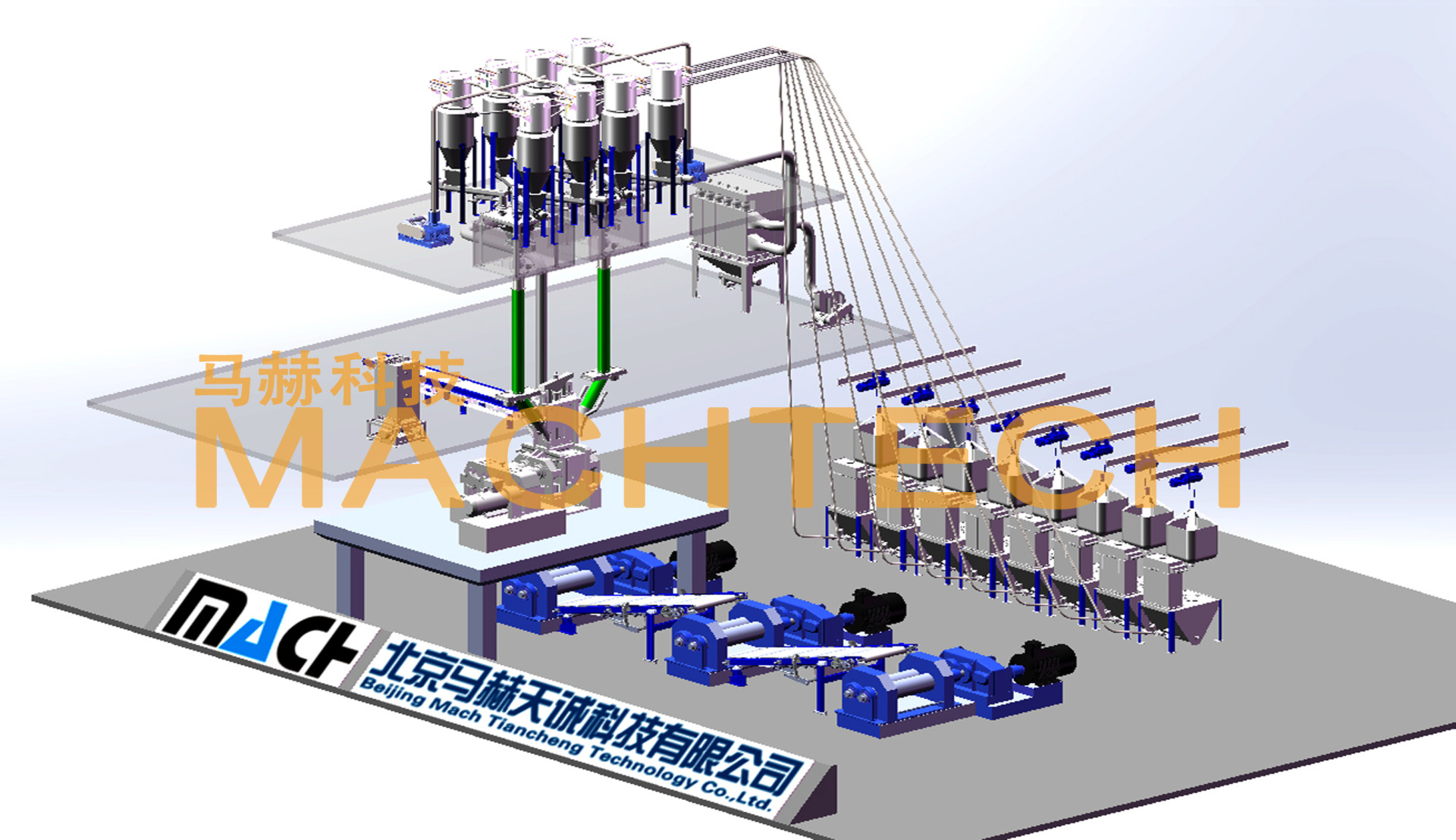

This system is an intelligent material (powder, granular, block, liquid, etc.) conveying, storage, metering, batching, and feeding system for the rubber, cable polymer materials, silicone rubber, friction materials, plastics, and other industries. It is independently developed by our company based on the introduction and absorption of advanced technologies from Germany and the UK. It can be used with various specifications of internal mixers/kneaders/high-mixers/mixers. It mainly consists of five parts: powder part, oil part, block material part, dust removal part, and the whole process control system. The whole process control system combines the latest information technology with production management and production processes, integrating production process control, production planning management, material management, and quality tracking management into one, truly achieving integrated control. It plays an important role in improving management level, product quality, and product stability. After years of continuous technological innovation and improvement by our company, this system has been widely used at home and abroad and has been well received by customers.

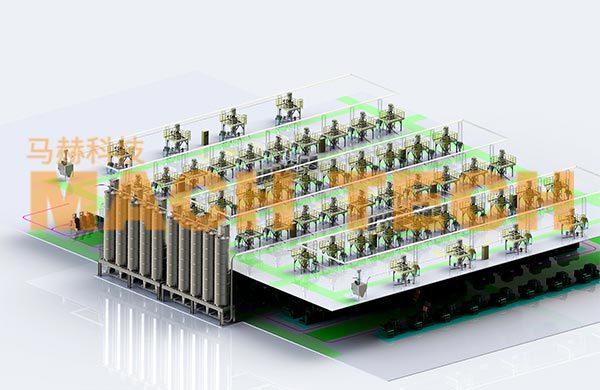

Centralized feeding system & large warehouse automatic storage system

A centralized material supply system is a material supply system used in industrial production. It achieves centralized management and efficient distribution of materials by transporting raw materials from a central storage area to multiple production equipment or workstations. A centralized material supply system is an efficient, reliable, and safe material supply system, which is of great significance to improving the efficiency and quality of rubber and plastic industrial production.

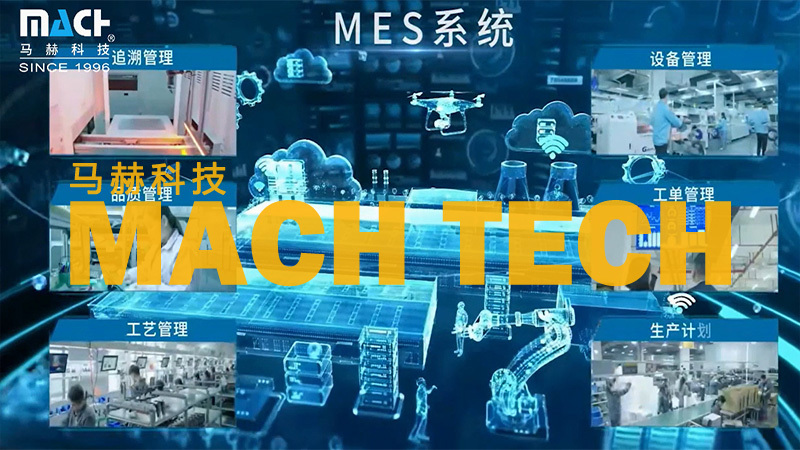

Intelligent Control System Mach-MES

The Maher Technology workshop intelligent control system adopts a modular and professional design for the plastics industry. Different modules can be selected to meet various user needs, resulting in stronger adaptability and shorter implementation cycles. With over 20 years of experience, Maher boasts extensive expertise in processes, equipment, production line data acquisition, and intelligent control. Our independently developed standardized control software is mature, stable, and cost-effective. We collaborate with clients to drive innovation and accelerate the transformation and upgrading of the plastics industry to "intelligent manufacturing."

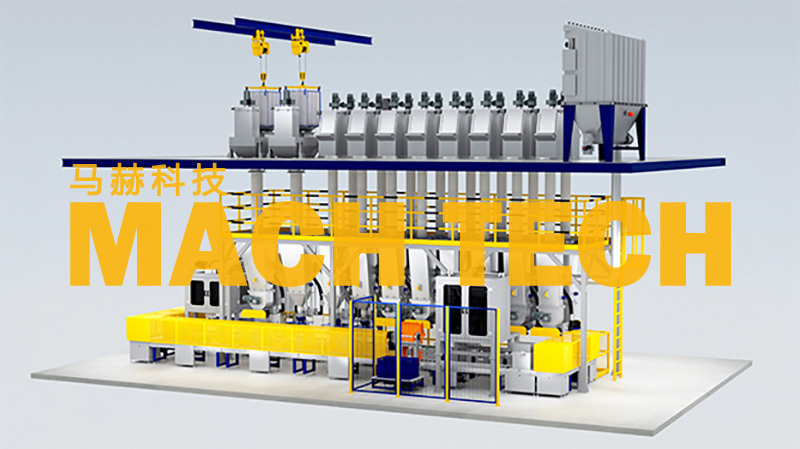

This system is mainly applicable to single-story and double-story factory buildings. Bulk materials are transported and metered sequentially using negative pressure suction. It meets the requirements of the main machine for the storage, transportation, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the main machine of the mixing mill and kneading mill.

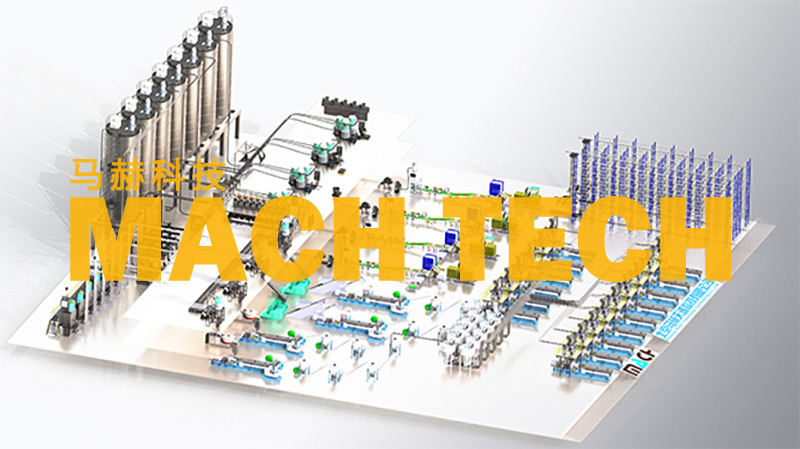

The automatic batching system for silica gel/insulators has the following advanced features compared with previous processes and equipment: 1. This system meets the requirements of dozens of kneading machines for the storage, batching, weighing, and feeding of precipitated/gas-phase white carbon black; 2. It realizes linkage control with the kneading machine, realizes the informatization management of the whole line, and improves the level of intelligent management; 3. It adopts modular group design, which is more convenient for equipment maintenance and repair, and the sub-station control and metering weighing operate independently to ensure a lower failure rate; 4. The intermittent feeding of the reduced-weight hopper meets the large-scale (500KG) batching of the silica gel meshing production process, avoiding large-capacity preparation hoppers. 5. It realizes continuous feeding, the feeding speed can be adjusted, and the metering is stable; 6. Continuous cumulative metering, one-time adjustment of the error value, realizes the metering requirements of large range and high precision; 7. Customized design, according to customer needs and actual conditions, provides the most suitable technical solutions and full personalized service to meet the future development needs of customers.

This system is mainly applicable to single-story factory buildings. Based on user requirements for precision, efficiency, and factory conditions, the system offers customized solutions in various forms, such as negative pressure, negative pressure + three-dimensional, small three-dimensional, and vertical screw, to complete the batching and metering process. It meets the requirements of kneading machines/mixing mills for the storage, conveying, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the main kneading machine/mixing mill. It is mainly used in the production of rubber, plastics, cable materials, food, pharmaceuticals, chemical raw materials, and other products.

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn