Products

Hot Products

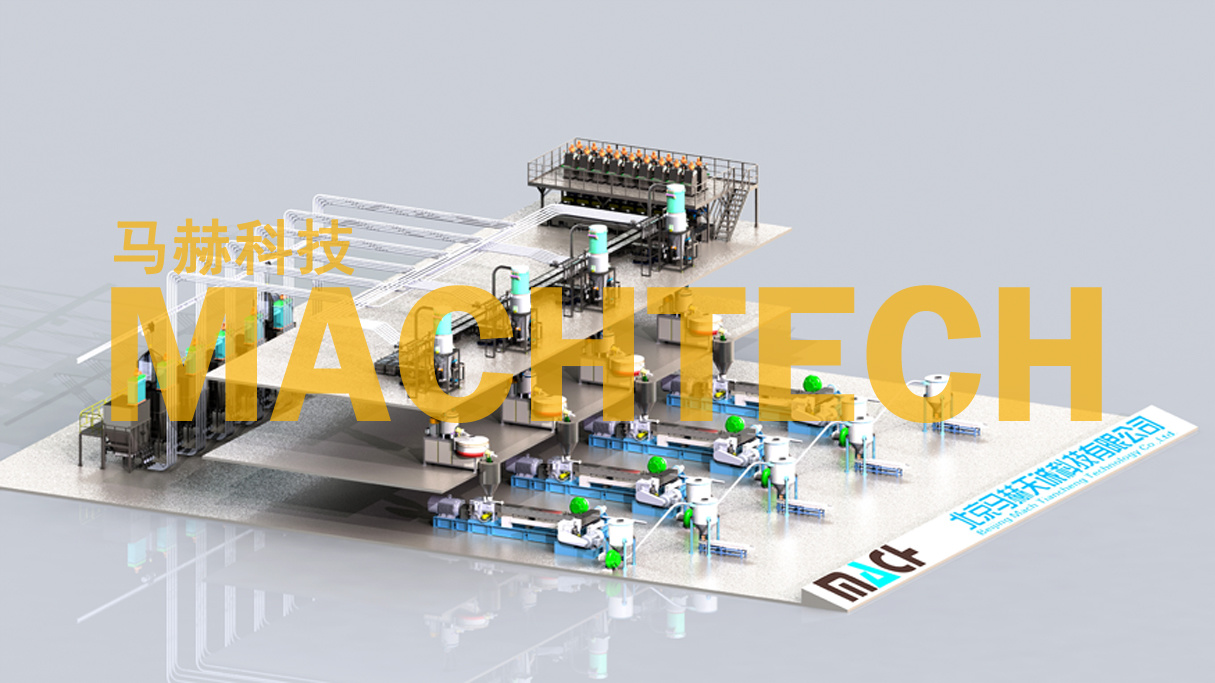

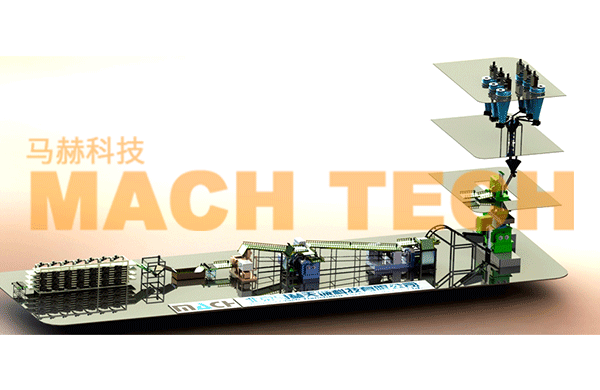

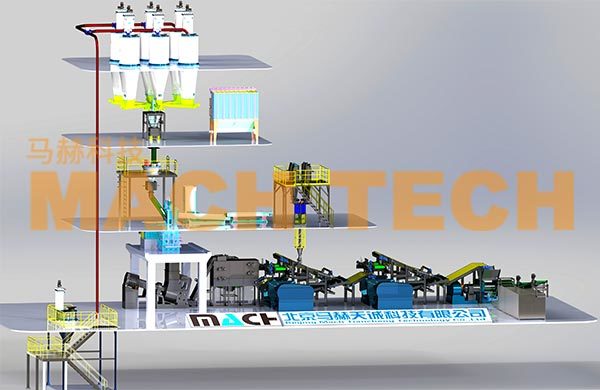

Masterbatch carrier/pigment automatic batching and mixing system

This system mainly realizes the automated production and full-process control of masterbatch products, targeting the storage, automatic weighing, batching, transportation, mixing, finished product storage, and environmental protection requirements of carrier raw materials, carriers (medium and small materials), pigments, and auxiliaries, and the linkage control with the kneader/mixer host, providing a complete automated production line. This system adopts a three-dimensional or planar structural design. The intelligent automatic batching system plays an important role in improving management level, product quality, and product stability.

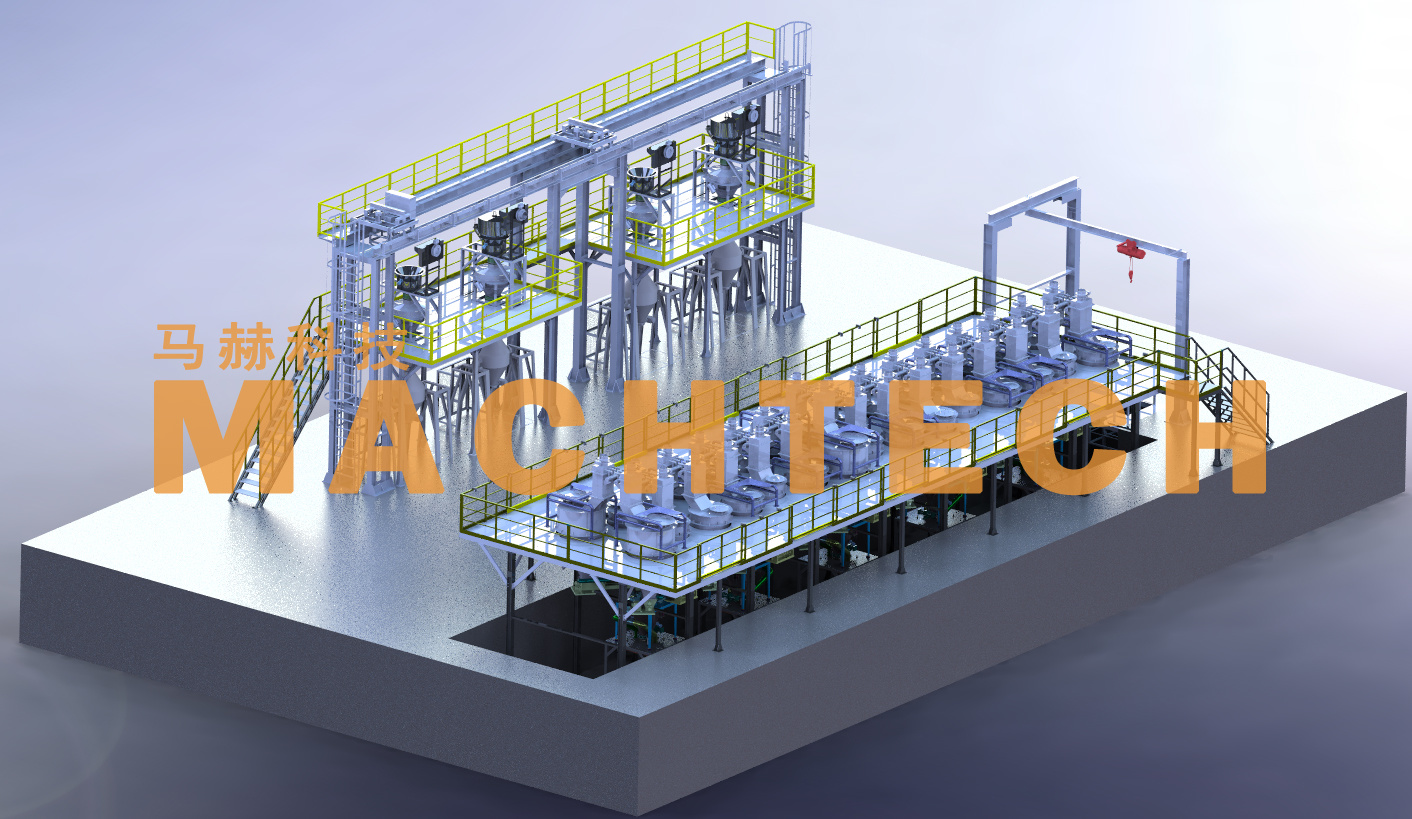

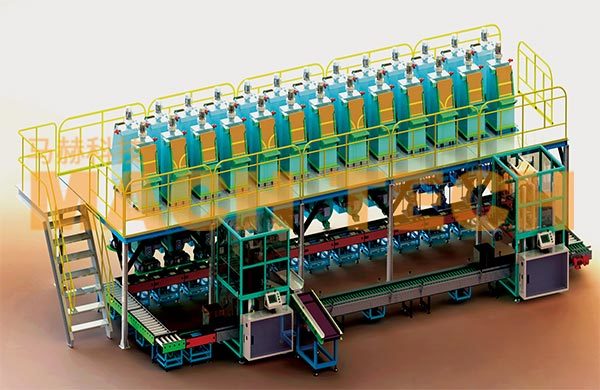

Automatic conveying, metering, batching and full process control system for magnetic materials

This system mainly realizes the automatic conveying, metering, and batching of magnetic materials, as well as the informatization management of the entire production process. It provides a customized equipment and software integrated solution targeting the requirements of storage, conveying, automatic weighing, batching, automatic logistics transportation, mixing, sintering/bonding/injection molding, finished product storage, environmental protection, and overall line informatization management of soft and hard magnetic materials.

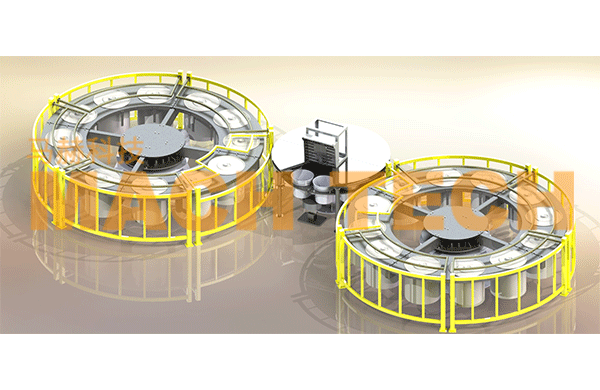

Automated production line and information management system for friction materials

This system primarily realizes the automated production and comprehensive management of various brake pads and clutch pads for trains and automobiles. It provides a complete automated production line addressing the requirements for raw material storage, automatic weighing, batching, transportation, mixing, coarse crushing, fine crushing, constant temperature storage, pressing and molding, grinding, testing, finished product storage, and environmental protection. The system adopts a three-dimensional or planar structural design. The intelligent automatic batching system plays an important role in improving management levels, product quality, and product stability. After years of continuous technological innovation and improvement by our company, this system has been well-received by customers.

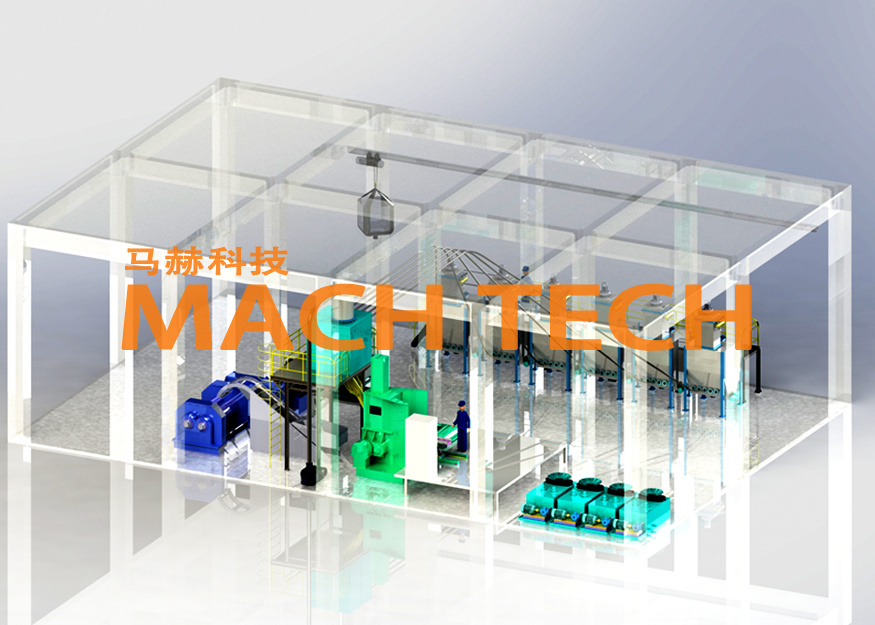

Next-generation welding material handling overall solution

Based on the reliable and stable equipment, this scheme adopts the design concept of "precise, efficient, and suitable." Through intelligent upgrades, it solves the problem of equipment production varying from person to person, helping customers improve overall production efficiency by 30% and continuously promoting the automation, intelligence, and informationization upgrades of the welding materials industry.

This system is mainly suitable for single-story and double-story factory buildings. Bulk materials are transported and metered using negative pressure suction. It meets the requirements of the main mixing/kneading machine for the storage, transportation, metering, batching, feeding, and dust removal of various raw materials, and realizes linkage control with the main mixing/kneading machine. It is mainly used in the production of rubber products, plastic products, cable materials, food, pharmaceuticals, chemical raw materials, etc. Main Features: This system offers flexible process layout options, resulting in low factory investment costs. It reduces the handling of bulk materials, separates raw material storage and unpacking from the production area, and maintains a clean environment. The unpacking device uses single-machine dust removal, resulting in no raw material loss, and achieves automated production and information management. It is mainly suitable for mixing and kneading machines with specifications below 160. Because the batching cycle is slower than that of a three-dimensional auxiliary machine, the mixing cycle is generally required to be around 6 minutes. Granulated raw materials are better suited for use. The use of special materials that are prone to moisture absorption and caking requires confirmation.

Series one-time rubber refining system

Features of the Series Once-Through Rubber Refining System 1. The series-type internal mixer completes the final refining and mother refining processes in one pass, increasing production capacity by approximately 100%; 2. Both mother refining and final refining use the same PLC for online control of rubber refining quality fluctuations; The mixed rubber uses a one-pass mixing method, which can improve the mechanical shearing efficiency of the rubber, making the carbon black and various compounding agents more evenly dispersed, improving the tensile strength, wear resistance, and fatigue resistance of the rubber, reducing the Mooney viscosity, and other physical properties, improving the quality of the mixed rubber and products; 3. Filling powder and small auxiliary agents are all closed-loop transported and closed-loop mixed, resulting in less pollution; 4. The rotor dustproof seal wear ring uses C-C composite material and requires only a small amount of oil. This reduces oil contamination of the rubber and saves more than 40% of oil compared to traditional methods; 5. Using a series-type internal mixer greatly shortens the auxiliary time; 6. Reduces the number of open mixers and other auxiliary equipment used; 7. Using a series-type internal mixer reduces the floor space of the rubber refining workshop and saves on civil construction investment; 8. Using a fully automatic open mixer greatly reduces the labor intensity of workers; 9. Because of the vulcanization in the lower internal mixer, the open mixer refines rubber at below 90 degrees, and the rubber cooling machine does not produce smoke.

Positive pressure dense phase low-speed high-concentration (dual-pipe, single-pipe) pneumatic conveying system is a product with internationally advanced technological level independently developed by our company based on the introduction of advanced pneumatic conveying technology from Germany and combined with many years of practical experience.

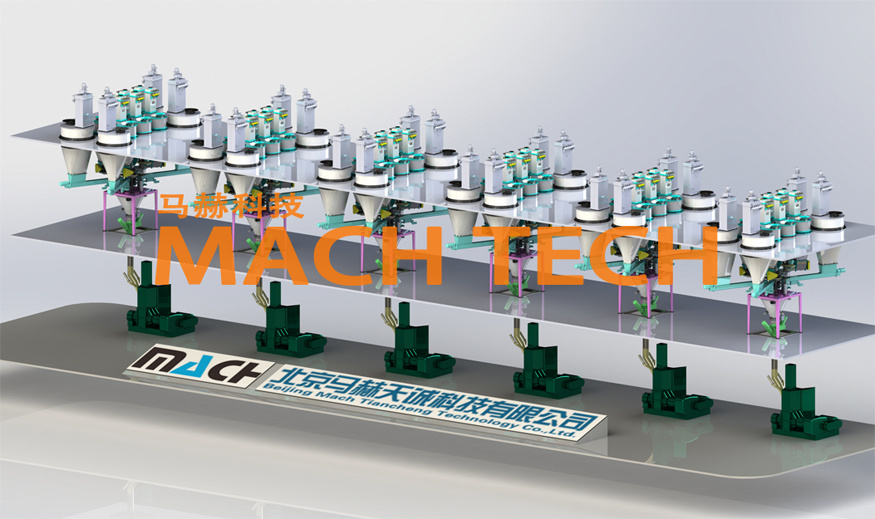

Intelligent multi-station high-precision small material weighing and batching system

This system is an intelligent, fully automated, high-precision material (granular, powdery, flake, etc.) metering and batching system independently developed by our company based on the introduction and absorption of advanced material batching technology from Japan and Germany. It is designed for the rubber, cable polymer materials, silicone rubber, friction materials, plastics, and color powder industries. The system uses various feeding methods such as electromagnetic vibration, double (single) screw, belt conveying, self-cleaning screw, and vibrating screw feeding, along with a continuous stepless speed regulation intelligent control device. Multiple electronic scales are individually set and driven to achieve automatic control management of the material weighing and batching process according to user needs, ensuring uniform and stable batching accuracy. The system is equipped with complete environmental protection and automatic bagging and bagging equipment.

Low-temperature one-step rubber refining system

1. One-step mixing of the compound improves the efficiency of mechanical shearing, resulting in more uniform dispersion of carbon black and various compounding agents. This effectively avoids carbon black gelation during mixing, reduces irreversible chemical scission of rubber molecular chains, increases the number of reversible mechanically sheared molecular chains, improves the tensile strength, abrasion resistance, and fatigue resistance of the compound, reduces Mooney viscosity, and improves other physical properties, thus enhancing the quality of both the compound and the product. 2. A kneader vulcanization system is used, with kneaders arranged in series and parallel to improve the dispersion of sulfur. 3. Energy consumption is reduced compared to traditional processes that use energy-intensive internal mixers for multi-stage mixing; energy savings are approximately 25%. 4. The production capacity of the internal mixer is also maximized. The average number of mixing stages is 1.6, meaning a 1.6-fold increase in production capacity. 5. The automation level of the final mixing line is improved. 6. The quality of the compound is uniform and stable. 7. Labor and management costs are reduced.

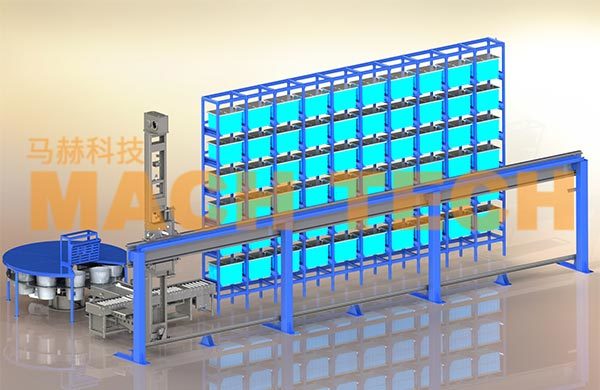

Unit storage shelves: pallet type, bin type

Unit storage rack: Made of profiles, can be arbitrarily combined and installed, easy to install, and easy to adjust the height of the storage location. In addition to storing pallets and boxes, after laying the shelf beams, it can store any goods that do not exceed the size of the grid.

Beijing Mach Tiancheng Technology Co., Ltd.

Address: 12th Floor, Building B, Yu Hui Building, No. 73 Fucheng Road, Haidian District, Beijing

Telephone:86 010-88152355

Fax: 010-88133042

Email:xiayanqiu@machtech.com.cn